Hot tag

Popular search

The Ultimate Buyer's Guide to Coax Feeder 1/2: Everyhing You Need Before & After

The article is designed to assist novice users in becoming experts in using Coax Feeder 1/2. Whether you are new to the world of coaxial feeders or looking to enhance your knowledge and skills, this guide is tailored to meet your needs.

Seamless connectivity is crucial in today's fast-paced and interconnected world. Coax Feeder 1/2 plays a vital role in achieving this, as it ensures reliable and efficient transmission of signals. Whether you are setting up a communication network, installing a broadcasting system, or establishing a wireless infrastructure, understanding and harnessing the power of Coax Feeder 1/2 is essential for optimal performance.

This buyer's guide will provide you with comprehensive insights, practical tips, and expert advice to navigate the intricacies of Coax Feeder 1/2. By the end of this guide, you will have the knowledge and confidence to make informed decisions, set up Coax Feeder 1/2 with precision, troubleshoot common issues, and future-proof your connectivity solutions.

Embark on this journey from being a novice to becoming a pro in working with Coax Feeder 1/2. Let us equip you with the necessary knowledge and tools to unlock the full potential of this technology and achieve seamless connectivity in your applications.

Understanding the Basics of Coax Feeder 1/2

The coax feeder 1/2 is a significant component in telecommunication systems and is widely used for transmitting high-frequency signals. It plays a crucial role in ensuring efficient transmission and minimizing signal loss.

Designed with precision and reliability in mind, the coax feeder 1/2 is primarily composed of high-quality materials that provide excellent electrical and mechanical properties. This feeder is constructed using a combination of an inner conductor, a dielectric insulating layer, and an outer conductor, all carefully engineered to optimize signal propagation.

The inner conductor, typically made of solid copper or copper-plated steel, serves as the central path for signal transmission. It is shielded by the dielectric insulating layer, which is often constructed using materials such as foam polyethylene or air-spaced dielectric. This insulating layer ensures that the signal remains contained within the conductor, preventing interference and maintaining signal integrity.

To shield the inner conductor and dielectric insulator from external interference, the coax feeder 1/2 utilizes an outer conductor, commonly referred to as the shield. This shield is typically made of copper or aluminum, providing a protective barrier against electromagnetic interference and reducing signal loss due to external factors.

In addition to its structural components, the coax feeder 1/2 may also include a protective outer jacket made of materials like polyethylene or PVC. This jacket provides an extra layer of insulation, shielding the feeder from environmental factors such as moisture, UV radiation, or mechanical stresses.

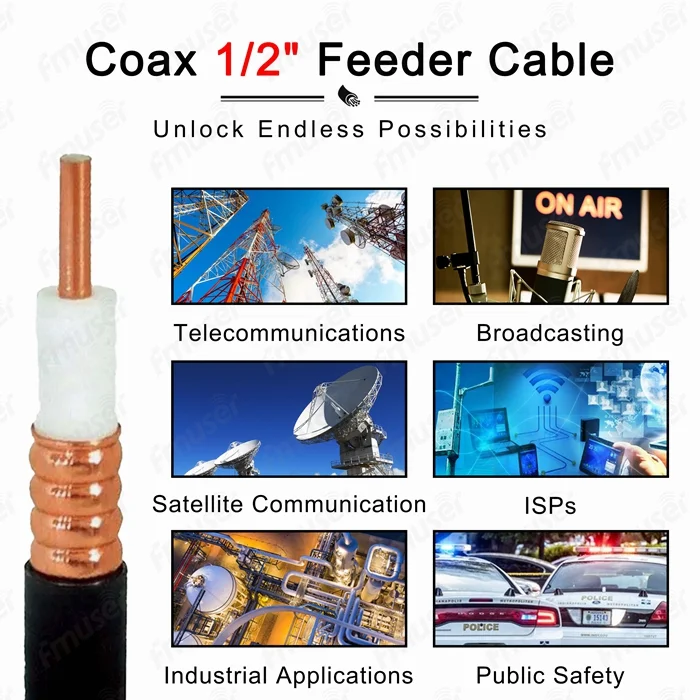

Coax Feeder 1/2 Applications

Coax Feeder 1/2 is a versatile coaxial cable that finds extensive use in various industries and applications. Its excellent performance characteristics make it well-suited for demanding environments where reliable signal transmission is crucial. Here are some of the main applications where Coax Feeder 1/2 is commonly used:

- Telecommunications: Coax Feeder 1/2 plays a vital role in telecommunications systems, including cellular networks, wireless communication networks, and base station installations. It is used for connecting antennas, repeaters, and other communication equipment, ensuring efficient signal transmission over long distances.

- Broadcasting: Coax Feeder 1/2 is widely employed in broadcasting applications, both in radio and television broadcasting. It is used for transmitting audio and video signals from broadcasting studios to transmission towers or satellite uplink facilities. The cable's low signal loss and high-frequency capabilities make it ideal for delivering clear and reliable broadcast signals.

- Data Networks: Coax Feeder 1/2 is utilized in data network installations, such as Ethernet and local area networks (LANs). It provides a reliable medium for transmitting data signals with minimal interference or loss, making it suitable for high-speed data transfer over extended distances.

- CCTV Systems: Coax Feeder 1/2 is commonly employed in closed-circuit television (CCTV) systems for video surveillance. It ensures the high-quality transmission of video signals from cameras to monitoring or recording devices. The cable's durability and shielding capabilities make it ideal for outdoor and long-distance CCTV installations.

- Wireless Internet Service Providers (WISPs): Coax Feeder 1/2 is widely used by wireless internet service providers for establishing reliable connections between network access points and customer premises equipment. It enables the transmission of high-speed internet signals over long distances, ensuring seamless connectivity for customers.

- Military and Defense: Coax Feeder 1/2 is utilized in military and defense applications, including communication systems, radar systems, and electronic warfare systems. Its rugged construction and high-performance characteristics make it suitable for withstanding harsh operating conditions and maintaining secure and reliable communication links.

- Industrial Applications: Coax Feeder 1/2 is found in various industrial settings, such as manufacturing facilities, power plants, and transportation systems. It is used for monitoring and control systems, interconnecting critical equipment, and transmitting signals for process automation and control.

These are just a few examples of the main applications where Coax Feeder 1/2 is commonly used. Its versatility, durability, and excellent signal transmission capabilities make it a reliable choice for a wide range of industries and applications where efficient communication and data transfer are essential.

Customized Solutions for Your Needs

At FMUSER, we pride ourselves on offering turnkey solutions that are tailored to meet the specific requirements of our customers. As the largest supplier of antenna-feeder equipment, measuring equipment, radio monitoring equipment, and related products, we understand the importance of providing customized solutions that optimize performance and minimize costs.

1/2" RF Coax Feeder Cable In Stock & Ship Same Day:

https://www.fmradiobroadcast.com/product/detail/1-2-feeder-cable.html

Our customized approach allows us to eliminate unnecessary components and focus on delivering exactly what our customers need. By understanding your unique requirements, we can design and provide solutions that perfectly match your specifications. Here are some of the services we offer:

1. Customized Feeder Cable Lengths:

Our feeder cables are packaged as 500m (1640ft) per roll. However, we understand that different projects may require specific cable lengths. We offer customized feeder cable lengths to ensure you get the exact length you need for your application. Whether it's a shorter length or a longer run, we can accommodate your requirements.

2. Customized Branding and Marking:

We understand the importance of branding and recognition for your business. That's why we offer the option to mark your logo, company name, phone number, and web address on the wooden drums and cables themselves. Additionally, we print a unique drum number on every wooden drum, allowing us to track the quality of the product in the future.

3. Special Product Customization:

In addition to our standard product offerings, we have the capability to customize special products based on your requirements. If you have specific engineering parameters such as IMD (Intermodulation Distortion), VSWR (Voltage Standing Wave Ratio), or plating preferences, we can discuss the details and produce the product according to your specifications. Simply show us your drawing, sample, or provide us with the indicated details, and we will work with you to bring your vision to life.

4. Varies Feeder Cables In-stock

At FMUSER, we take pride in offering a complete product manufacturing line of RF feeder cables. We understand that every project has unique requirements, which is why we provide a wide range of coaxial feeders with different sizes, including 1/2", 1-5/8", 7/8", and more. Here are some key points about our varied feeder cables in-stock:

- Unmatched Versatility: Our inventory of feeder cables covers a spectrum of sizes to cater to diverse applications. Whether you need a smaller diameter like 1/2" for local area networks or a larger diameter like 1-5/8" for high-power broadcasting, we have the options to meet your specific needs.

- Optimal Performance: Each of our feeder cables is engineered to deliver optimal performance and ensure reliable signal transmission. Our expertise and commitment to quality guarantee that our cables meet industry standards and provide excellent signal integrity for your critical projects.

- Precise Specifications: Our varied feeder cables come with precise specifications, including impedance, attenuation, and power handling capabilities. This allows you to select the cable that best matches your system requirements, ensuring seamless integration and optimal performance.

- Low-cost Solutions: At FMUSER, we understand the importance of cost-effectiveness. We strive to provide low-cost solutions, both in terms of production and selling prices. By offering competitive pricing, we aim to lower your buying costs and provide exceptional value for your investment.

- Exceptional Durability: Our feeder cables are built to withstand the rigors of demanding environments. They are constructed with high-quality materials, ensuring durability, resistance to moisture, UV radiation, and extreme temperatures. With our feeder cables, you can trust in long-lasting performance.

5. Shipment & Packaging

FMUSER is committed to providing outstanding shipment and packaging services for our RF feeder cables. We ensure that your products are delivered swiftly and securely, meeting your expectations and guaranteeing customer satisfaction. Here are some important points to know about our shipment and packaging services:

- Fast and Reliable Delivery: We understand the urgency of timely deliveries. Our efficient logistics team ensures that your RF feeder cables reach you as quickly as possible, minimizing delays and keeping your projects on track.

- Secure Packaging: We prioritize the safety of your products during transit. Our RF feeder cables are expertly packaged to withstand the challenges of shipping, ensuring they arrive in pristine condition. Our packaging solutions protect against potential damage, providing you with peace of mind.

- Customized Packaging Options: We offer customized packaging options to suit your specific requirements. Whether you need labeling, special handling instructions, or specific packaging materials, we can accommodate your needs to ensure hassle-free delivery.

- Attention to Detail: We pay meticulous attention to every aspect of the shipment and packaging process. Our dedicated team ensures that your order is accurately fulfilled, carefully packaged, and promptly dispatched, exceeding your expectations at every step.

At FMUSER, we belieave in providing the best prices and features for all your needs. We specialize in manufacturing coaxial cable accessories and are dedicated to supporting telecommunication tower components, installation solutions, and designing new products for base station infrastructures. Our product range includes coaxial connectors, feeder cables, cable clamps, grounding & lightning protection, wall cable entry systems, pulling grips, and more.

We strongly advise using our trade form or contacting us directly to place an order or discuss specific requirements. Our team is always ready to assist you and ensure that your customized solutions are designed, produced, and delivered to meet your expectations. With FMUSER, you can trust in our commitment to providing high-quality, customized solutions for your telecommunication needs.

Coax Feeder 1/2 Connectors

Coax Feeder 1/2 utilizes specific connectors to ensure proper and secure connections between the cable and other system components. These connectors are designed to maintain the cable's impedance and minimize signal reflections.

Connector Types

Here are some commonly used connectors for Coax Feeder 1/2:

- N-Type Connector: The N-Type connector is a widely used RF connector known for its excellent performance and robustness. It provides reliable connections and is commonly used in various applications, including telecommunications, broadcast systems, and wireless networks. N-Type connectors are typically used as both input and output connectors for Coax Feeder 1/2.

- 7/16 DIN Connector: The 7/16 DIN connector is a high-power RF connector known for its low loss and high reliability. It is commonly used in applications that require high power handling capabilities, such as cellular networks and broadcast systems. 7/16 DIN connectors are suitable for both input and output connections in Coax Feeder 1/2.

- 7/8 EIA Connector: The 7/8 EIA connector is specifically designed for use with Coax Feeder 7/8", which has a larger diameter than Coax Feeder 1/2. It provides secure and low-loss connections and is widely used in high-power applications, including broadcasting and long-distance wireless links.

- Type N Connector: The Type N connector is a medium-sized RF connector that offers good performance and versatility. It is commonly used in various applications, including telecommunications, broadcast systems, and industrial environments. Type N connectors can be used as both input and output connectors for Coax Feeder 1/2.

- BNC Connector: The BNC connector is a compact RF connector known for its ease of use and quick connections. It is commonly used in video and audio applications, such as CCTV systems and broadcast equipment. BNC connectors can be used as input connectors for Coax Feeder 1/2, especially in video transmission applications.

Choosing Coax Feeder 1/2 Connectors

When choosing connectors for Coax Feeder 1/2, it's important to consider various factors to ensure compatibility and optimal performance. Here are some key points to consider:

- Impedance Matching: Ensure that the chosen connectors are compatible with the impedance of Coax Feeder 1/2, which is typically 50 or 75 ohms. Maintaining impedance consistency throughout the system minimizes signal reflections and ensures proper signal transmission.

- Power Handling: Consider the power levels that will be transmitted through the connectors. Choose connectors that can handle the expected power levels without causing signal loss or damage.

- Environmental Factors: Evaluate the environmental conditions where the connectors will be installed. Consider factors such as moisture, temperature variations, and exposure to harsh conditions. Choose connectors that offer appropriate protection against these elements.

- Connector Type: Consider the specific requirements of your application and the compatibility with the equipment you are connecting to. Each connector type has its own advantages and use cases. Ensure that the chosen connectors are suitable for your specific application.

- Quality and Reliability: Select connectors from reputable manufacturers known for their quality and reliability. This ensures long-term performance and minimizes the risk of connection issues or signal loss.

By considering these factors, you can choose the appropriate connectors for Coax Feeder 1/2, ensuring reliable and secure connections for your system. If you have any specific questions or require further guidance, consult with experts in the field or reach out to reputable suppliers who can provide expert advice tailored to your unique requirements and application.

Coax Feeder 1/2 Terminologies

In this section, we will delve into the professional specifications of Coax Feeder 1/2, providing a comprehensive understanding of the technical aspects and terminologies associated with this high-performance coaxial cable. These specifications are essential for selecting, installing, and optimizing the performance of Coax Feeder 1/2 in your specific applications.

Construction Materials

The construction materials used in Coax Feeder 1/2 are vital for its overall performance, durability, and suitability for various environments. Each component serves a specific purpose and contributes to the cable's functionality. Understanding these materials is crucial for making informed decisions and ensuring optimal performance in your installations.

- Inner Conductor: The inner conductor of Coax Feeder 1/2 is responsible for carrying the electrical signal. It is typically made of copper-clad aluminum wire (CCA). This composite wire combines the conductivity of copper with the lightweight properties of aluminum. The inner conductor's material affects the cable's conductivity, signal transmission efficiency, and overall performance.

- Dielectric: The dielectric material used in Coax Feeder 1/2 plays a crucial role in maintaining signal integrity and preventing signal loss. It serves as an insulating barrier between the inner conductor and the outer conductor. Coax Feeder 1/2 commonly utilizes physical foam polyethylene (PFPE) as the dielectric material. PFPE is known for its low-loss properties, ensuring efficient signal propagation with minimal attenuation.

- Outer Conductor: The outer conductor of Coax Feeder 1/2 provides shielding against external electromagnetic interference, preventing signal degradation and maintaining signal integrity. It typically consists of a corrugated copper tube. The corrugations increase the surface area of the outer conductor, enhancing its electrical conductivity and ensuring effective shielding.

- Jacket: The jacket of Coax Feeder 1/2 is the outermost layer that provides protection to the cable against environmental factors, physical damage, and moisture. It is typically made of materials like polyethylene (PE). The jacket helps maintain cable integrity, durability, and flexibility, making it suitable for various indoor and outdoor applications.

Understanding the construction materials of Coax Feeder 1/2, including the inner conductor, dielectric, outer conductor, and jacket, is essential for ensuring the cable's performance, durability, and compatibility with your specific applications. These materials work together to provide reliable signal transmission, protection against environmental conditions, and longevity for your coaxial cable installation.

Physical Dimensions

The physical dimensions specification of Coax Feeder 1/2 refers to the size and diameter of the various components of the cable. Understanding these dimensions is crucial for proper installation, compatibility with connectors and other components, and ensuring optimal performance. Let's explore the importance of physical dimensions and the following specifications:

- Inner Conductor Diameter: The inner conductor diameter specification indicates the size of the central conductor within Coax Feeder 1/2. It represents the diameter of the copper-clad aluminum wire that carries the electrical signal. The inner conductor diameter is essential for ensuring compatibility with connectors and maintaining proper signal transmission within the coaxial cable.

- Dielectric Diameter: The dielectric diameter specification refers to the size of the physical foam polyethylene used as the insulating material within Coax Feeder 1/2. This dimension is important for maintaining the proper spacing between the inner and outer conductors, minimizing signal loss, and ensuring efficient signal propagation.

- Outer Conductor Diameter: The outer conductor diameter specification represents the size of the corrugated copper tube that surrounds the dielectric material. It is crucial for compatibility with connectors, ensuring proper fit and a secure connection. The outer conductor diameter also plays a role in the overall shielding effectiveness of the coaxial cable, protecting the signal from external interference.

- Diameter Over Jacket: The diameter over jacket specification refers to the overall diameter of Coax Feeder 1/2, including the outer jacket. This dimension is important for determining the cable's compatibility with cable routing pathways, conduits, and connectors. It ensures that the cable fits properly within installation spaces and allows for efficient and reliable connections.

Understanding the physical dimensions of Coax Feeder 1/2, such as the inner conductor diameter, dielectric diameter, outer conductor diameter, and diameter over the jacket, is essential for proper installation, compatibility, and overall performance. These specifications ensure that the cable fits within designated spaces, maintains signal integrity, and enables reliable connectivity in your specific applications.

Mechanical Specifications

The mechanical specifications of Coax Feeder 1/2 focus on the cable's mechanical properties and its ability to withstand physical stress and environmental conditions. Understanding these specifications is crucial for ensuring proper installation, durability, and reliable performance. Let's explore the importance of mechanical specifications and the following key terms:

- Single Bending: The single bending specification indicates the cable's ability to bend without causing damage or negatively impacting its performance. It refers to the maximum bending radius that the Coax Feeder 1/2 can safely withstand in a single bend without experiencing signal loss or structural damage. Adhering to the single bending specification helps maintain signal integrity and cable longevity.

- Repeated Bending: The repeated bending specification refers to the cable's capability to withstand multiple bending cycles without degradation or failure. It represents the cable's resistance to fatigue over time. Coax Feeder 1/2 with a higher repeated bending specification can endure frequent movement or flexing without compromising signal quality or overall performance.

- Minimum Number of Bends: The minimum number of bends specification indicates the minimum number of times the cable can be bent without experiencing damage or failure. It is essential to follow this specification to prevent signal loss, insulation breakdown, or structural issues over the cable's lifespan. Exceeding the minimum number of bends could lead to performance degradation or cable failure.

- Tensile Strength: The tensile strength specification measures the maximum pulling force or tension the Coax Feeder 1/2 can withstand without breaking or experiencing damage. It is crucial for installations where the cable may be subject to tension, such as overhead or long-distance applications. Proper consideration of the tensile strength specification ensures the cable remains intact and maintains its performance under mechanical stress.

Understanding the mechanical specifications of Coax Feeder 1/2, including single bending, repeated bending, minimum number of bends, and tensile strength, is essential for proper installation, durability, and overall performance. Adhering to these specifications ensures the cable's ability to withstand physical stress, maintain signal integrity, and deliver reliable connectivity in various environments and applications.

Environmental Specifications

The environmental specifications of Coax Feeder 1/2 refer to the cable's ability to operate and withstand varying environmental conditions. Understanding these specifications is crucial for selecting the appropriate cable for specific applications and ensuring reliable performance in different settings. Let's explore the importance of environmental specifications and the following key terms:

- Storage Temperature: The storage temperature specification indicates the range of temperatures within which Coax Feeder 1/2 can be safely stored without risking damage or performance degradation. Adhering to this specification is important to ensure the cable's integrity and protect it from potential issues caused by extreme temperatures during storage.

- Installation Temperature: The installation temperature specification refers to the range of temperatures at which Coax Feeder 1/2 can be safely installed. It is crucial to consider this specification during the installation process to prevent potential damage or physical stress on the cable caused by extreme temperatures.

- Operating Temperature: The operating temperature specification represents the range of temperatures within which Coax Feeder 1/2 can function optimally. It ensures that the cable can maintain its performance and signal integrity under varying temperature conditions. Operating the cable within the specified temperature range is essential for reliable signal transmission and longevity.

Understanding the environmental specifications of Coax Feeder 1/2, including storage temperature, installation temperature, and operating temperature, is vital for selecting the appropriate cable for specific environments and ensuring reliable performance. Adhering to these specifications helps protect the cable from potential damage or degradation caused by extreme temperature conditions, ensuring optimal signal transmission and longevity in various applications.

Electrical Specifications

The electrical specifications of Coax Feeder 1/2 outline the cable's electrical characteristics and performance parameters. Understanding these specifications is crucial for ensuring proper signal transmission, compatibility with the system, and optimal performance. Let's explore the importance of electrical specifications and the following key terms:

- Capacitance: The capacitance specification measures the ability of Coax Feeder 1/2 to store an electrical charge. It is important as it affects the cable's ability to transmit high-frequency signals with minimal distortion. Lower capacitance values indicate better signal quality and reduced signal loss.

- Impedance: The impedance specification refers to the characteristic resistance to the flow of an electrical signal in Coax Feeder 1/2. It is important for matching the cable's impedance with the connected devices or systems. Coax Feeder 1/2 typically has an impedance of 50 or 75 ohms, ensuring efficient signal transmission and compatibility with devices designed for specific impedance.

- Velocity: The velocity specification represents the speed at which electrical signals travel through Coax Feeder 1/2 relative to the speed of light. It is expressed as a percentage. A high velocity ensures minimal signal delay, efficient data transfer, and accurate signal reproduction.

- 4. RF Peak Voltage: The RF peak voltage specification indicates the maximum voltage that Coax Feeder 1/2 can handle without risking signal distortion or damage. It is important for ensuring the cable can withstand voltage spikes or surges commonly associated with RF signals.

- Peak Power Rating: The peak power rating specification defines the maximum power that Coax Feeder 1/2 can handle without experiencing performance degradation or damage. It helps determine the cable's suitability for high-power applications and ensures reliable signal transmission.

- Cut-off Frequency: The cut-off frequency specification represents the maximum frequency at which Coax Feeder 1/2 can effectively transmit signals. Beyond this frequency, the cable may experience significant signal loss or attenuation. Understanding the cut-off frequency is essential when working with high-frequency applications.

- Shielding Effectiveness >10MHz: The shielding effectiveness specification ensures that Coax Feeder 1/2 provides sufficient shielding against unwanted external electromagnetic interference. It specifies the level of protection the cable offers against interference frequencies higher than 10MHz.

- Insulation Resistance: The insulation resistance specification measures the resistance to current leakage through the insulation material of Coax Feeder 1/2. Higher insulation resistance values indicate better insulation quality, reducing the risk of signal loss or leakage.

- VSWR (Voltage Standing Wave Ratio): The VSWR specification indicates the ratio of the maximum amplitude of a standing wave to the minimum amplitude. It measures the amount of reflected power in the cable and helps ensure proper impedance matching for optimal signal transfer.

Understanding the electrical specifications of Coax Feeder 1/2, including capacitance, impedance, velocity, RF peak voltage, peak power rating, cut-off frequency, shielding effectiveness, insulation resistance, and VSWR, is crucial for selecting the appropriate cable, ensuring compatibility, and maintaining optimal signal transmission performance. These specifications contribute to reliable signal transfer, efficient data transmission, and overall system performance.

Buying Factors of Coax Feeder 1/2

Selecting the appropriate Coax Feeder 1/2 for your specific application is crucial to ensure optimal performance and seamless connectivity. Consider the following factors when making your selection:

Choosing Coax Feeder 1/2 for Radio Broadcast Systems

When selecting Coax Feeder 1/2 for your radio broadcast system, it's important to consider various factors to ensure optimal performance and reliability. Here are some key buying factors to consider before placing any orders:

- Frequency Range: Determine the frequency range required for your radio broadcast system. Coax Feeder 1/2 is capable of handling a wide range of frequencies, but specifying the desired range will help ensure compatibility with your system.

- Power Handling: Consider the power levels that will be transmitted through the cable. Coax Feeder 1/2 has specific power handling capabilities, so it's crucial to select a cable that can handle the expected power without signal loss or damage.

- Signal Loss: Assess the acceptable signal loss for your system. Coax Feeder 1/2 has moderate signal loss, but understanding your specific requirements will help determine if additional measures such as signal boosters or amplifiers are necessary.

- Environmental Conditions: Evaluate the environmental conditions where the cable will be installed. Consider factors such as exposure to moisture, UV radiation, extreme temperatures, or potential physical stress. Ensure that the chosen Coax Feeder 1/2 has appropriate protection against these conditions.

- System Integration: Consider compatibility with other system components such as antennas, transmitters, and receivers. Ensure that the connectors and impedance match those of your system to minimize signal reflections and optimize performance.

- Installation Distance: Determine the length of cable required for your radio broadcast system. Coax Feeder 1/2 is available in standard lengths, but if a longer or shorter cable run is needed, customization options may be necessary.

- Budget: Consider your budget for the project. Compare prices from reputable suppliers to ensure you are getting the best value for your investment without compromising quality.

- Consult with Experts: If you have any doubts or questions, consult with experts in the field or reach out to reputable suppliers who can provide expert advice and guidance.

If you have any specific questions or require further assistance, feel free to contact us. Our team of experts is dedicated to providing tailored solutions and expert advice to meet your unique requirements.

Installation and Setup

Proper installation and setup of Coax Feeder 1/2 are crucial for achieving optimal performance and ensuring seamless connectivity. Follow these step-by-step guidelines to ensure a successful installation:

1. Cable Routing:

- Plan the cable routing path, considering factors such as distance, ease of access, and avoiding potential sources of interference. Keep the cable away from power lines, sources of electromagnetic interference, and sharp bends that could cause signal loss or damage.

- Use appropriate cable clamps and supports to secure the Coax Feeder 1/2 along the routing path, ensuring that it is properly supported and protected.

2. Connectors:

- Select high-quality connectors suitable for Coax Feeder 1/2, ensuring compatibility with the cable's impedance and specifications. Common connector types include N-type or 7/16 DIN connectors.

- Follow the manufacturer's instructions and use proper techniques for installing connectors, including proper cable stripping, center conductor preparation, and secure attachment. Use the appropriate tools and techniques to achieve a reliable and low-loss connection.

3. Grounding:

- Proper grounding is essential for safety and to minimize potential electrical hazards. Install grounding kits at both ends of the Coax Feeder 1/2 to ensure proper grounding and to protect against lightning or electrical surges.

- Follow local electrical codes and guidelines for grounding practices. Consult with professionals if needed to ensure compliance with safety regulations.

4. Weatherproofing:

- If installing Coax Feeder 1/2 in outdoor or exposed areas, consider weatherproofing measures to protect the cable and connectors from moisture or environmental conditions.

- Apply weatherproofing tape or sealant to connectors, use weatherproof enclosures or protective sleeves, and ensure proper sealing where the cable enters buildings or other structures.

Best Practices for Setting Up and Configuring Coax Feeder 1/2:

- Perform a thorough visual inspection of the cable to ensure there are no visible damages or defects before installation.

- Use cable length calculations and minimize the use of unnecessary connectors or splices to reduce signal loss.

- Maintain proper bend radius guidelines for Coax Feeder 1/2 to prevent signal degradation. Avoid sharp bends or kinks that can alter the cable's electrical characteristics.

- If required, use appropriate installation tools such as cable cutters, crimping tools, grounding kits, and weatherproofing materials to ensure a professional and secure installation.

By following these guidelines for installation, cable routing, connector selection, grounding, weatherproofing, and adhering to best practices, you can ensure that your Coax Feeder 1/2 is set up correctly for optimal performance. This will result in reliable signal transmission and seamless connectivity for your applications.

Upgrading and Future-Proofing

As technology evolves, it's important to assess the need for upgrading existing Coax Feeder 1/2 installations to keep pace with emerging requirements. Understanding how to evaluate the need for upgrades and considering future-proofing measures will help ensure that your Coax Feeder 1/2 setup remains compatible with evolving technologies.

1. Assessing the Need for Upgrades:

- Performance Evaluation: Regularly evaluate the performance of your Coax Feeder 1/2 installation to identify any limitations or bottlenecks. Consider factors such as signal quality, bandwidth requirements, and data transfer rates.

- System Requirements: Assess whether your current Coax Feeder 1/2 setup meets the demands of your applications. If you experience frequent signal degradation, capacity limitations, or inadequate coverage, it may be time to consider an upgrade.

- Technology Advancements: Stay updated on industry trends and advancements in coaxial cable technology. Assess whether newer versions of Coax Feeder 1/2 offer improved performance, wider bandwidth, or greater efficiency that aligns better with your current or future requirements.

2. Future-Proofing Considerations:

- Bandwidth Capacity: Consider the anticipated growth in bandwidth requirements for your applications. Look for Coax Feeder 1/2 options that can accommodate higher frequencies and bandwidths to ensure compatibility with future technologies.

- Compatibility with Emerging Technologies: Evaluate the compatibility of your Coax Feeder 1/2 installation with emerging technologies such as 5G, IoT, or increased data rates. Consider whether your current setup can support these advancements or if an upgrade is necessary.

- Scalability: Assess the scalability options of your current Coax Feeder 1/2 setup. Determine if it can easily accommodate additional connections or increased transmission capacity as your network expands or evolves over time.

- Longevity: Consider the expected lifespan of your current Coax Feeder 1/2 installation and compare it to the desired longevity of your network infrastructure. Upgrading to newer versions that offer enhanced durability and longevity can help future-proof your setup.

By regularly evaluating performance, assessing system requirements, monitoring technology advancements, and considering future-proofing measures, you can make informed decisions about upgrading your Coax Feeder 1/2 installation. Upgrading when necessary and considering compatibility with emerging technologies will ensure that your network remains adaptable, efficient, and future-ready.

FAQs

1. What is Coax Feeder 1/2?

Coax Feeder 1/2 is a type of coaxial cable that is widely used in telecommunications and broadcasting applications. It consists of an inner conductor, dielectric material, outer conductor, and protective jacket.

2. What is the difference between 50 ohm and 75 ohm Coax Feeder 1/2?

The difference lies in the impedance value. 50 ohm Coax Feeder 1/2 is commonly used in data transmission, networking, and RF applications. On the other hand, 75 ohm Coax Feeder 1/2 is often used for video and audio signal transmission, such as in broadcasting and cable TV.

3. What are the advantages of using Coax Feeder 1/2?

Coax Feeder 1/2 offers several benefits, including low signal loss, high signal integrity, excellent shielding against interference, and wide frequency range capabilities. It is also durable, easy to install, and suitable for both indoor and outdoor applications.

4. What is the maximum transmission distance of Coax Feeder 1/2?

The maximum transmission distance of Coax Feeder 1/2 depends on various factors such as signal strength, frequency, and system components. However, it can typically support transmission distances of several hundred meters without significant signal degradation.

5. Can Coax Feeder 1/2 be used for digital signals?

Yes, Coax Feeder 1/2 can be used for digital signals. It has a wide bandwidth and offers excellent transmission characteristics, making it suitable for carrying high-speed digital signals.

6. How do I choose between different coaxial cable sizes?

The choice of coaxial cable size depends on factors such as the desired frequency range, power requirements, and system impedance. Coax Feeder 1/2 is often chosen for its balance of performance and cost-effectiveness, but it's always recommended to consult a professional or refer to specific application guidelines.

7. Can I use connectors from different manufacturers with Coax Feeder 1/2?

Yes, Coax Feeder 1/2 is designed to be compatible with standard coaxial connectors. However, it's important to ensure that the chosen connectors are suitable for the cable's impedance and specifications to maintain optimal performance.

8. Can Coax Feeder 1/2 be used for outdoor installations?

Yes, Coax Feeder 1/2 is commonly used for outdoor installations. It is designed to provide protection against environmental conditions and is often UV-resistant and weatherproof, making it suitable for various outdoor applications.

These are just a few frequently asked questions about Coax Feeder 1/2. If you have any further inquiries or specific concerns, it is always recommended to consult with experts or professionals in the field to ensure the best application of Coax Feeder 1/2 for your specific needs.

Wrap-up

In conclusion, Coax Feeder 1/2 is a versatile and reliable coaxial cable that offers excellent signal transmission capabilities for various applications. With its physical dimensions, professional specifications, environmental specifications, and electrical specifications, Coax Feeder 1/2 provides reliable performance, low signal loss, and wide frequency range capabilities.

Understanding the basics and expertise of Coax Feeder 1/2 is crucial for selecting the right cable, connectors, and accessories for your project. Whether you need to set up a telecommunications network, broadcasting system, data network, or any other application requiring reliable signal transmission, Coax Feeder 1/2 is designed to meet your needs.

To ensure the success of your project, it is essential to partner with an experienced and reliable supplier like FMUSER. We offer turnkey solutions, expertise in coaxial cable accessories, and a commitment to providing high-quality products and excellent customer service. Contact us today to discuss your requirements, receive expert advice, and find the perfect solutions for your communication needs.

Choose Coax Feeder 1/2 and FMUSER for reliable signal transmission, optimized performance, and seamless connectivity. Get in touch with us now to take your projects to the next level!

Contents

CONTACT US

FMUSER INTERNATIONAL GROUP LIMITED.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us