RF Rigid Line & Parts

FMUSER’s Rigid Coaxial Transmission Line, Parts, and Accessories (also known as hardline or rigid line) are engineered to deliver low-loss, high-power RF signal transmission for industries like broadcasting, telecom, and defense.

Introduction & Overview: Precision Engineered for RF Excellence

A rigid coaxial transmission line is a type of guided wave transmission line used in high-frequency RF communication systems to transmit radio frequency signals with low loss from one point to another. It consists of a hollow metal pipe inside another hollow metal pipe, both with coaxial symmetry, with a dielectric material in between them.

Some other synonyms of rigid coaxial transmission line include:

- Hardline

- Rigid line

- Rigid coaxial cable

- Hardline coaxial cable

- Hardline coax

- Rigid coax

- Rigid cable

- Rigid transmission line

- Rigid waveguide

- Rigid RF cable

Combining coaxial symmetry (hollow inner/outer metal pipes with dielectric insulation) and robust shielding, these lines excel in harsh environments while minimizing electromagnetic interference. FMUSER categorizes solutions by frequency range (DC–6 GHz) and power handling (1–50 kW) to streamline selection for projects ranging from 5G tower deployment to emergency broadcast systems.

Key Features: Built to Outperform

- Ultra-Low Signal Loss: Air or pressurized-gas dielectric reduces attenuation to <0.1 dB/100ft, ensuring clarity over long distances.

- Military-Grade Durability: Corrosion-resistant copper/aluminum alloys withstand extreme temperatures, moisture, and mechanical stress.

- Superior Shielding: Coaxial symmetry neutralizes external noise, critical for radar systems and satellite communications.

- Industry-Leading Power Handling: Supports 10 kW+ continuous power without degradation, ideal for FM/AM radio broadcast towers.

- Plug-and-Play Flexibility: Pre-flanged connectors (N-type, DIN) and compatibility with waveguide systems simplify integration.

Diverse Applications: Where FMUSER’s Solutions Shine

- Broadcast Infrastructure: Uninterrupted Signal Delivery: Hardline cables ensure 24/7 studio-to-tower transmission with near-zero latency. Benefit: Crisp audio/video quality even over 50+ mile spans.

- Telecom & 5G Networks: Future-Proof Backhaul: Rigid lines handle mmWave frequencies and Massive MIMO configurations. Benefit: Seamless integration with Huawei, Ericsson, or Nokia base stations.

- Defense Systems: Secure, Mission-Critical Links: Tamper-proof designs maintain signal integrity for shipboard radar and drone communications. Benefit: MIL-STD-810G compliance for shock/vibration resistance.

- Satellite Ground Stations: Space-Grade Reliability: FMUSER’s rigid waveguide-compatible lines reduce uplink/downlink noise. *Benefit:_ NASA-tested performance for GEO/LEO operations.

Why Choose Us: Turnkey Solutions for Rigid Line Expertise

- Factory-Direct Pricing: Save 30%+ with in-house production of hardline coax and accessories.

- Global Stock, Fast Shipping: 3-day delivery to US/EU ports; urgent orders fulfilled in 48h.

- OEM Customization: Specify lengths (1m–100m), flange types (CPR-159G, UG-599), and pressurization kits.

- Lifetime Support: Free site surveys, CAD drawings, and 24/7 troubleshooting via FMUSER’s RF engineers.

- Proven in Action: Deployed with BBC, Lockheed Martin, and China Mobile for emergency broadcast and naval radar systems.

-

![Rigid Line Tubes for Rigid Coaxial Transmission Line]()

-

![Matching Sections for Coaxial Rigid Transmission Line]()

-

![Inner Support for Rigid Transmission Line]()

-

![Flange Inner Support for Rigid Transmission Line]()

-

![Flange to Unflanged Adapter for Rigid Transmission Line]()

-

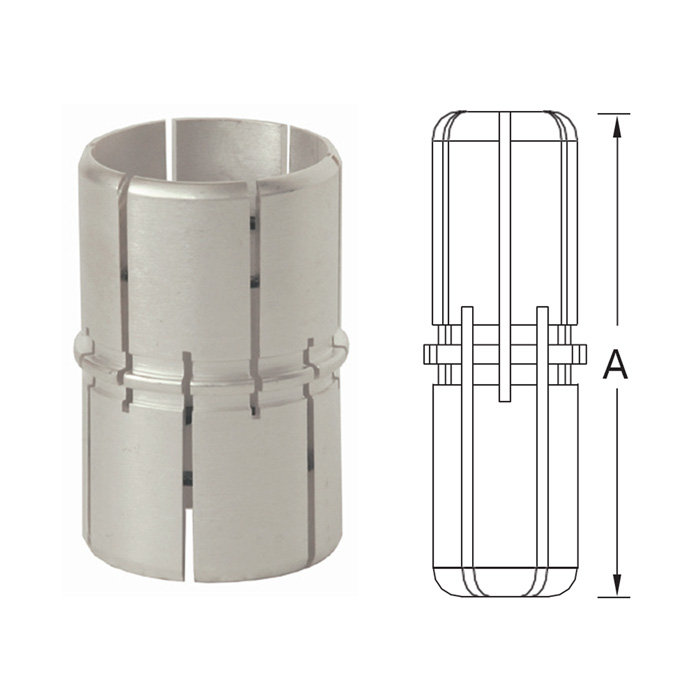

![Outer Sleeve for Rigid Transmission Line]()

-

![Inner Bullet for Rigid Transmission Line]()

-

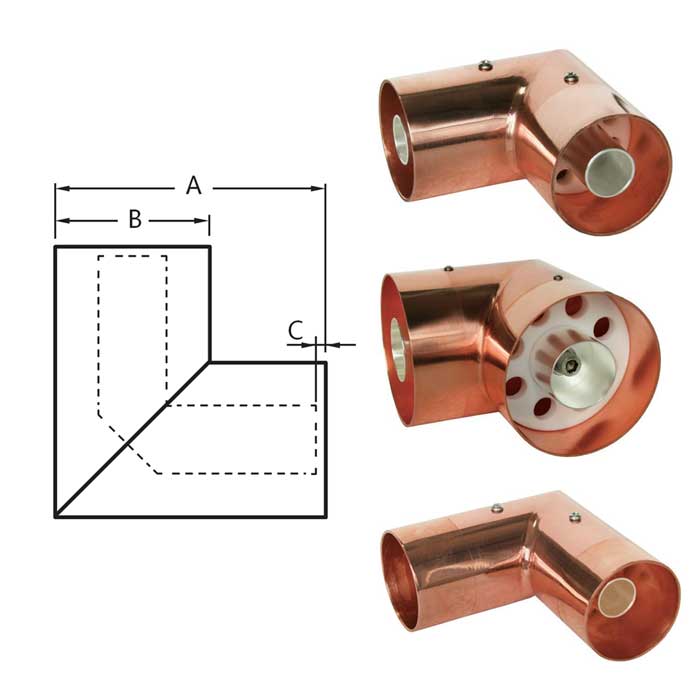

![Silver-plated Brass Elbows for Rigid Transmission Line Connection]()

Silver-plated Brass Elbows for Rigid Transmission Line Connection

Price(USD):Ask for a quotation

Sold:1,498

-

![Coaxial Adaptors for Rigid Transmission Line to Coaxial Cable Connection]()

Coaxial Adaptors for Rigid Transmission Line to Coaxial Cable Connection

Price(USD):Ask for a quotation

Sold:1,011

-

![Rigid Coaxial Transmission Line for FM, TV, and AM Station]()

- What are common terminologies of rigid coaxial transmission line?

- Here are some key terminologies related to rigid coaxial transmission lines in RF communication, along with explanations of what these terms mean.

1. Outer Diameter (OD): The outer diameter is the measurement of the diameter of the outer conductor of the transmission line. It typically ranges from a few millimeters to several centimeters, depending on the application.

2. Inner Diameter (ID): The inner diameter is the measurement of the diameter of the inner conductor of the transmission line. The ID is typically much smaller than the OD, and is typically measured in millimeters.

3. Length: The length of a rigid coaxial transmission line is the distance between the two connection points. The length is an important factor to consider when designing a system, as it affects the overall propagation time and signal attenuation.

4. Inner Conductor: This is the center conductor of the transmission line, which is usually made of high conductivity copper or silver-plated copper. The inner conductor serves to carry the electrical signal along the length of the line.

5. Outer Conductor: This is the cylindrical metal shield that surrounds the inner conductor. The outer conductor serves to provide shielding from electromagnetic interference and to return the electrical signal to its source.

6. Dielectric Material: The dielectric material is the insulating material used between the inner and outer conductors, typically made of Teflon or a similar material. The dielectric constant of the material determines the impedance of the line.

7. Impedance: Impedance is a measure of the resistance to the flow of electrical current. The impedance of a rigid coaxial transmission line is typically 50 Ohms or 75 Ohms, and is determined by the geometry and dielectric constant of the line.

8. Frequency Range: The frequency range is the range of frequencies over which the transmission line can transmit signals with low loss. This range is determined by the dimensions and material properties of the line.

9. Power Handling Capacity: The power handling capacity of a transmission line refers to the maximum power level that can be transmitted through the line without damage to the line or other components in the system. This value is determined by the size and material of the line.

10. Cost: The cost of a rigid coaxial transmission line depends largely on the diameter, length, type of material, and other factors mentioned above. In general, larger diameter lines and longer lengths are more expensive, as are lines made from higher-quality materials.

11. VSWR (Voltage Standing Wave Ratio): VSWR is a measure of the ratio of the maximum amplitude to the minimum amplitude of the signal in a transmission line. It indicates how closely the impedance of the line matches the impedance of the source and load. VSWR values of 1.5 or less are considered good for most applications.

12. Insertion Loss: Insertion loss is the amount of signal power lost when a signal is transmitted through a transmission line. It is typically measured in decibels (dB) and can be affected by the length, size, material, and quality of the line. Lower insertion loss is generally desirable for high-performance systems.

13. Velocity of Propagation: The velocity of propagation is the speed at which an electromagnetic wave travels through a transmission line. It is typically measured as a fraction of the speed of light and varies depending on the type of dielectric material used in the line.

14. Flange Size: Flange size refers to the size of the mounting flange on either end of a rigid coaxial transmission line. These flanges are typically used to attach the transmission line to other system components, such as antennas or amplifiers. The size and spacing of the flanges are important factors to consider when designing a system.

15. Temperature Rating: The temperature rating of a transmission line refers to the maximum or minimum temperature that the line can safely operate at. This rating is determined by the type of material used in the line and its melting or breakdown point.

16. Application Specific Terminology: Lastly, there are some other terminologies or specifications that may be specific to certain rigid coaxial transmission line applications. For example, certain transmission lines may have unique shape or curvature, or may be made from a specific type of material to meet specific environmental requirements. It is important to consider all relevant specifications and requirements for a given application when selecting a transmission line.

17. Phase Velocity: Phase velocity is the rate at which the phase of a sinusoidal wave propagates through a transmission line. It is defined as the ratio of the frequency of the wave to the wavelength, and is dependent on the dielectric constant and magnetic permeability of the materials used in the transmission line.

18. Attenuation: Attenuation is the reduction in amplitude of a signal as it travels down a transmission line. It is caused by various factors, including magnetic and dielectric losses, resistive losses, and radiative losses, among others. The amount of attenuation depends on the frequency and length of the transmission line, as well as the materials used.

19. Group Velocity: Group velocity is the rate at which the envelope of a wave packet propagates through a transmission line. It is determined by the dispersion characteristics of the materials used in the line. Group velocity is important for understanding how rapidly information can be transmitted through a transmission line.

20. Insertion Loss Variation (ILV): ILV is a measure of the variation in insertion loss across a given frequency range. It provides information about the consistency of the transmission line’s performance under different conditions and is important for applications requiring precise signal transmission.

21. Environmental Ratings: Depending on the application, a rigid coaxial transmission line may need to meet specific environmental ratings, such as ingress protection (IP) ratings for water and dust resistance, or environmental stress screenings (ESS) for resistance to vibration and temperature cycling. These ratings can affect the choice of materials and manufacturing processes used in the transmission line.

22. Calibration Kit: A calibration kit is a set of measurement standards used to calibrate a vector network analyzer (VNA) for accurate measurements of transmission line performance. The kit may include components such as open circuit, short circuit, and impedance standards to ensure accurate measurements of VSWR, insertion loss, and other parameters.

23. Frequency Stability: Frequency stability refers to the ability of a transmission line to maintain its transmission characteristics over time and under varying environmental conditions. Factors such as temperature, pressure, and humidity can affect the stability of a transmission line’s performance, making frequency stability an important consideration for high-precision applications.

24. Phase Shift: Phase shift measures the difference in phase angle between the input and output signals of a transmission line. It is affected by factors such as frequency, length, and the materials used in the line.

25. Shielding Effectiveness: Shielding effectiveness is a measure of the ability of a transmission line’s outer conductor to shield the inner conductor from electromagnetic interference. Higher levels of shielding effectiveness are generally preferred, especially for sensitive applications.

26. Standard Connector Type: A standard connector type is a common type of connector used to attach a transmission line to other components in an RF communication system. Examples of standard connector types include SMA, BNC, and N-type connectors.

27. Bend Radius: Bend radius is the minimum radius at points where a rigid coaxial transmission line is bent. This value is important to consider when installing a transmission line, as excessive bending can cause degradation in performance.

28. Impedance Matching: Impedance matching is the process of ensuring that the impedance of a transmission line matches the impedance of other components in the system, such as an amplifier or antenna. Impedance mismatches can cause reflections and other issues that can degrade system performance.

- What parts and accessories are needed for rigid coaxial transmission lines?

- The complete parts and accessories of a rigid coaxial transmission line for an RF broadcasting system may include the following components:

1. Coaxial line: This is the main component of the transmission line which consists of a solid copper outer conductor and a hollow copper inner conductor. It is used to transmit high power RF signals from the source to the antenna.

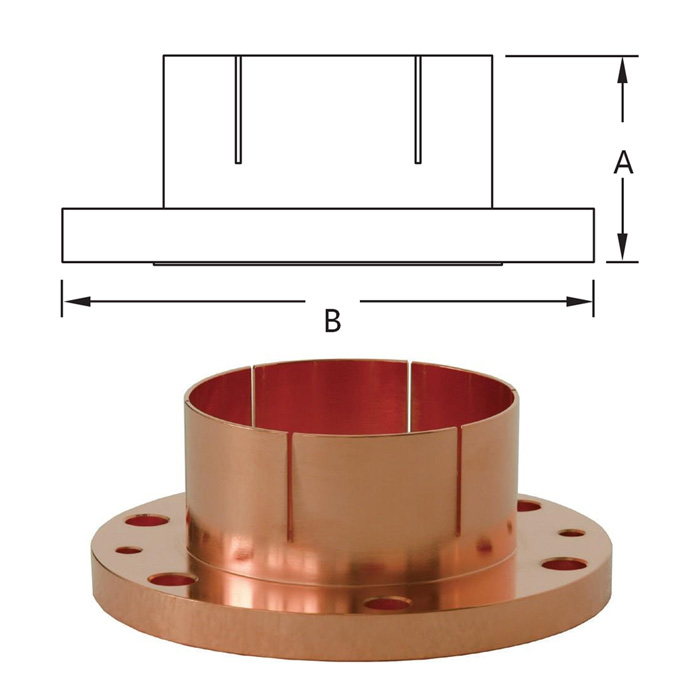

2. Flanges: These are the metal connectors that are used to join the coaxial line to other components such as the transmitter, receiver, and antenna.

3. Inner conductor: This is the hollow copper pipe that extends through the center of the coaxial line and carries the RF signal.

4. Dielectric material: This is a non-conductive material which is used to separate the inner and outer conductors of the coaxial line. It helps to maintain the impedance of the line and reduces signal loss.

5. Outer conductor: This is a solid copper tube which surrounds the dielectric material and provides shielding from external interference.

6. Grounding kits: These kits are used to ground the coaxial transmission line to protect it from lighting strikes and other electrical surges.

7. Attenuators: These are passive devices that are used to reduce the amplitude of the RF signal in the coaxial line. They are used to match the impedance of the transmission line to that of the antenna.

8. Couplers: These are passive devices used to split or combine RF signals in the coaxial line. They are used to route RF signals to multiple antennas.

9. Terminators: These are passive devices which are used to terminate the coaxial line when it is not being used. They help to prevent reflections and signal loss.

10. Waveguide adapters: These are components used to join a coaxial line to a waveguide, which is used to transmit higher frequency signals.

Overall, the components of a rigid coaxial transmission line for an RF broadcasting system are designed to ensure good signal quality, minimize signal loss, and protect the system from damage due to external surges and interference.

- What are common applications of rigid coaxial transmission line?

- Rigid coaxial transmission lines are often used in RF communication applications that require high power handling and low signal loss. Here are some common applications of rigid coaxial transmission lines:

1. Broadcasting: Rigid coaxial transmission lines are commonly used in broadcasting applications to transmit high power RF signals from the transmitter to the antenna. They offer low signal loss and high power handling capacity, making them a popular choice for radio and television broadcasting.

2. Satellite communication: Rigid coaxial transmission lines are also used in satellite communication systems to transmit and receive signals between the satellite and the ground station. The high power handling capacity of rigid coaxial transmission lines is particularly useful for transmitting signals to and from orbiting satellites.

3. Medical equipment: Rigid coaxial transmission lines are used in medical equipment such as MRI machines, CT scanners, and other diagnostic imaging equipment. The low signal loss and high power handling capacity of rigid coaxial transmission lines help ensure accurate and reliable imaging.

4. Military and defense: Rigid coaxial transmission lines are used in military and defense applications such as radar systems, communication systems, and electronic warfare. The high power handling capacity of rigid coaxial transmission lines makes them suitable for handling the high power levels used in military and defense applications.

5. Industrial applications: Rigid coaxial transmission lines are used in industrial applications such as plasma cutting, welding, and induction heating. The low signal loss and high power handling capacity make them ideal for transmitting high-frequency RF signals used in industrial processes.

6. Wireless communication: Rigid coaxial transmission lines are also used in wireless communication systems such as cellular networks and point-to-point microwave links. They are used to transmit RF signals between base stations and other components in the network.

7. Research and development: Rigid coaxial transmission lines are often used in research and development applications such as material characterization, microwave testing, and electromagnetic compatibility testing. They are used to transmit RF signals between test equipment and the device or system being tested.

8. Aviation communication: Coaxial transmission lines are also used in aviation communication systems such as radar and navigation systems. The low signal loss and high power handling capacity of rigid coaxial transmission lines make them suitable for handling the high power levels used in these systems.

In summary, rigid coaxial transmission lines are used in a wide range of applications that require high power handling and low signal loss. They are commonly used in broadcasting, satellite communication, medical equipment, military and defense, industrial applications, wireless communication, research and development, aviation communication.

- What are the common structures of an rigid coaxial transmission line?

- The common structures of a rigid coaxial transmission line used in RF communication include the following:

1. Coaxial line: The coaxial line is the main component of the transmission line. It consists of a solid copper outer conductor and a hollow copper inner conductor. The two conductors are separated by a dielectric material such as air, Teflon, or ceramic. The coaxial line is designed to transmit high-frequency signals with low signal loss.

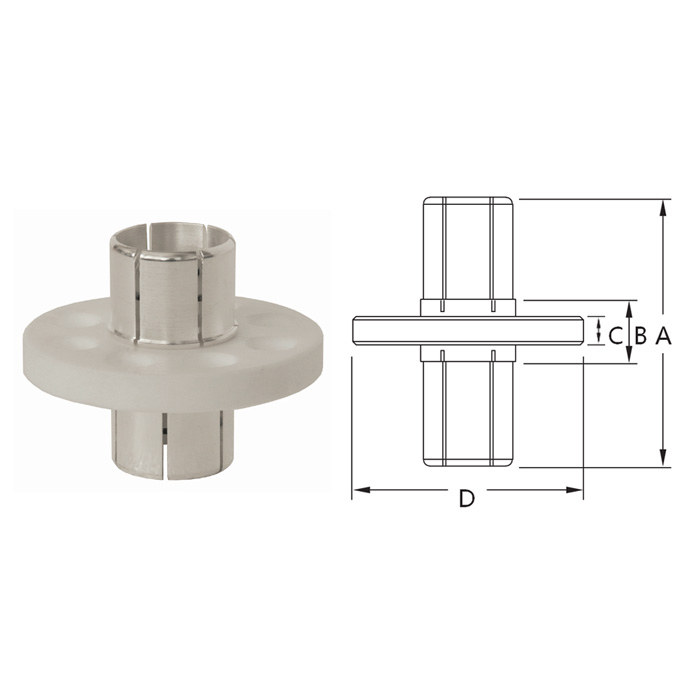

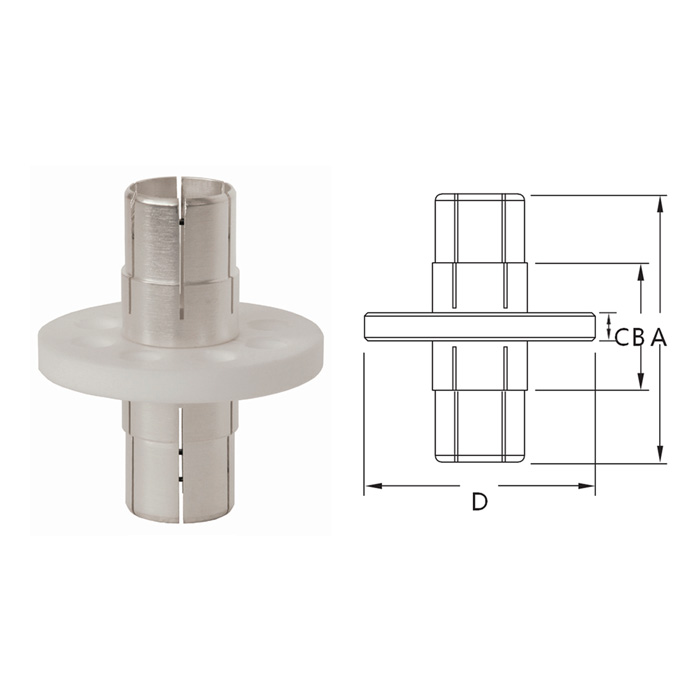

2. Inner bullet: The inner bullet, also known as the inner support, is a component of the flange. It is a protruding male connector that extends from the end of the coaxial line and features an inner pin which connects to the female part of the flange. The inner bullet is designed to maintain the proper spacing between the inner and outer conductors of the coaxial line.

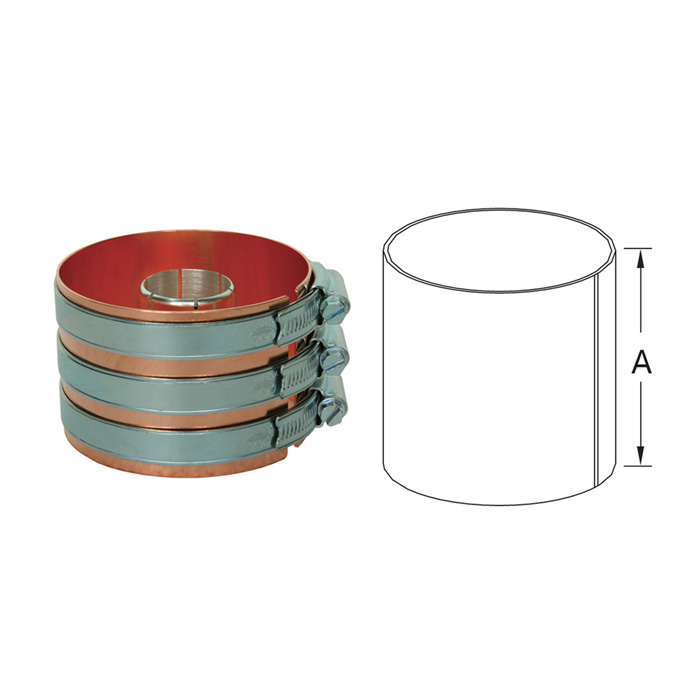

3. Outer sleeve: The outer sleeve is the female component of the flange. It fits over the end of the coaxial line and is secured in place by bolts. The outer sleeve compresses the inner support against the inner conductor of the coaxial line to create a secure and low-loss connection.

4. Elbows: Elbows are bent sections of coaxial line that are used to change the direction of the transmission line without incurring large losses. Elbows are typically designed to have a bend radius that matches the rest of the transmission line to ensure low-loss transmission.

5. Tee assemblies: Tee assemblies are used to split or combine RF signals in the coaxial line. They are designed in a T-shape and can have multiple input and output ports depending on the application.

6. Reducers: Reducers are used to match the size of a connector on the coaxial line to the size of the component it is connecting to.

7. Flanges: Flanges are the metal connectors that are used to join the coaxial line to other components such as the transmitter, receiver, and antenna. They typically consist of an inner support, outer sleeve, inner bullet, and elbows.

8. Gas barrier: Gas barriers are used to prevent gases from entering the transmission line, which can cause signal attenuation and degradation. They are made of materials such as Teflon and are designed to maintain the pressurized environment of the transmission line.

9. Anchor insulator connector: Anchor insulator connectors are used to suspend the coaxial line from a support structure using anchor insulators. They consist of a metal bracket that attaches to the insulator and a bolt that secures the coaxial line to the bracket.

10. Field flange: Field flanges are specialized flanges used in field installations that allow for a quick and easy installation without requiring specialized tools or equipment. They are typically designed to be lightweight and easy to handle.

11. Wall anchor plate: Wall anchor plates are used to securely attach the coaxial line to a wall or other surface. They are typically made of metal and have multiple bolt holes for attachment.

12. Hangers: Hangers are used to suspend the coaxial line from a support structure such as a tower or mast. They are designed to withstand wind and mechanical loads and can be fixed or spring-loaded to provide flexibility.

13. Patch panels: Patch panels are used to distribute RF signals to multiple components and typically include multiple ports for input and output. They can be fixed or modular and are designed to minimize signal loss.

Overall, the common structures of a rigid coaxial transmission line used in RF communication include a range of components that are designed to ensure good signal quality, minimize signal loss, and protect the system from damage due to environmental conditions and mechanical loads.

- How to correctly use and maintain an rigid coaxial transmission line?

- To ensure the correct usage and maintenance of a rigid coaxial transmission line used in RF communication, the following tips should be considered:

1. Proper Installation: Ensure that the coaxial line is installed properly and securely, minimizing stress on the line and connections.

2. Avoid Over-Bending: Over-bending the coaxial line can cause signal loss and degradation. Ensure that the bend radius does not exceed the recommended limit.

3. Use Proper Connectors: Use the appropriate connectors for the coaxial line and ensure that they are tightened properly to prevent signal loss due to loose connections.

4. Proper Grounding: Ensure that the coaxial line and all other components are properly grounded to prevent potential damage from lightning strikes or other electrical events. The grounding system should be regularly inspected for any signs of damage and maintained as needed.

5. Regular Inspections: The coaxial line, connectors, and other components should be inspected regularly for signs of corrosion or damage. Any damage should be addressed promptly to prevent signal degradation or failure.

6. Environmental Protection: Coaxial lines should be protected from environmental factors such as moisture, dirt, and extreme temperatures. The use of protective covers and weather-resistant materials can help prevent damage from these factors.

7. Regular Cleaning: Regularly cleaning the connectors and other components can prevent build-up of dust and debris that can cause signal loss and degradation.

8. Regular Testing: Regular testing of the coaxial line and system components can help identify any issues before they result in signal degradation or failure.

By following these tips, the lifespan of a rigid coaxial transmission line can be extended and the system can continue to provide reliable and high-quality RF communication.

- What are the most important specifications of an rigid coaxial transmission line?

- The most important physical and RF specifications of a rigid coaxial transmission line used in RF communication include the following:

1. Impedance: The characteristic impedance of the transmission line determines the amount of signal loss and reflection that occurs within the line. Common values for coaxial transmission lines include 50 ohms, 75 ohms, and 90 ohms.

2. Frequency Range: The frequency range of a coaxial transmission line determines the range of frequencies that can be transmitted with low signal loss. High frequency applications may require specialized or high-performance coaxial lines.

3. Insertion Loss: The insertion loss of a coaxial transmission line specifies the amount of signal loss that occurs when the signal passes through the line. Low insertion loss is crucial for high-quality and reliable RF communication.

4. VSWR: The voltage standing wave ratio (VSWR) specifies the amount of signal reflection that occurs within the transmission line. High VSWR values can cause signal degradation and can damage sensitive RF components.

5. Power Handling Capacity: The power handling capacity of a coaxial transmission line specifies the maximum amount of power that can safely be transmitted through the line. This specification is crucial for high-power RF applications.

6. Cable Length and Diameter: The length and diameter of a coaxial transmission line can affect the signal loss and insertion loss of the line. The length and diameter should be chosen based on the specific application requirements.

7. Dielectric Constant: The dielectric constant of the coaxial line's insulating material affects the characteristic impedance and transmission speed of the line. Common materials used include air, Teflon, and ceramic.

8. Connector Type: The connector type used with the coaxial transmission line should be appropriate for the specific application and should have low insertion loss and VSWR.

9. Operating Temperature Range: The operating temperature range of the coaxial transmission line should be appropriate for the specific application in order to prevent signal degradation or damage to the line.

Overall, selecting a coaxial transmission line with appropriate specifications for the specific RF communication application ensures optimal performance and reliability.

- How to choose the best rigid coaxial transmission lines for FM radio station?

- When choosing a rigid coaxial transmission line for an FM radio station, there are several factors to consider based on the power output, length, frequency range, connector type and accessories required.

1. Low Power FM Radio Station: For low power FM radio stations with power outputs less than 50 watts, a smaller and lower-cost 1/2 inch or 7/8 inch rigid coaxial transmission line with an impedance of 50 ohms is recommended. These cables offer low signal loss and are available with common connector types including BNC or N-Type connectors. Accessories like cable clamps, grounding kits, and termination blocks may also be required as well as jumper cables.

2. Medium Power FM Radio Station: For medium power FM radio stations with power outputs ranging from 50 to 1000 watts, a larger and higher power handling rigid coaxial transmission line like 1-5/8 inch or 3-1/8 inch series-coax is recommended. These cables offer low signal loss and higher power handling capacity, compared to smaller cables. The connectors used in this case could be type N, 7/16 DIN or EIA flange connectors. Accessories required may include jumper cables, splices, surge arrestors, grounding kits, and lightning arrestors.

3. High Power FM Radio Station: For high-power FM radio stations with power outputs higher than 1000 watts, larger rigid coaxial transmission lines like 4-1/16 inches or 6-1/8 inches series-coax may be required. The larger diameter of these cables helps to reduce signal loss and provide optimal signal quality. N-type, 7/16 DIN or EIA flange connectors are commonly used in high power applications. Accessories required may include dehydrators, splices, cooling systems, jumper cables and termination blocks.

The length of the rigid coaxial transmission line should be chosen based on the distance between the transmitter and antenna, and the specifications of the cable. Longer cable lengths result in higher signal loss so the length should be kept to a minimum. Careful attention must be paid to the power handling capacity of the chosen cable to ensure that it can handle the required power output.

Overall, selecting the right rigid coaxial transmission line for an FM radio station depends on factors such as power output, length, frequency range, connector type, and accessories required. Choosing the right cable and accessories will ensure optimal performance, reliability, and signal quality.

- How to choose the best rigid coaxial transmission lines for AM broadcast station?

- When choosing a rigid coaxial transmission line for an AM broadcast station, several factors must be considered, such as power output, frequency range, line length, connector type, and required accessories.

1. Low Power AM Broadcast Station: For a low power AM broadcast station, a smaller and lower-cost 7/8 inch or 1/2 inch rigid coaxial transmission line with an impedance of 50 ohms can be used. These cables can handle power outputs up to 5 kilowatts and are an ideal choice for small-scale AM broadcast stations with a lower power output. The connectors used in this case could be commonly available connector types such as N-type or BNC.

The length of the rigid coaxial transmission line for a low power AM broadcast station should be kept as short as possible to minimize signal loss. Rigid coaxial transmission lines with a lower characteristic impedance can be used for low power applications. These cables offer better signal transmission, and impedance matching can also help to improve the signal quality.

In terms of accessories for a low power AM broadcast station, it would depend on the specific requirements of the station. In most cases, jumper cables, grounding kits, and termination blocks, and a dehydrator are important accessories. These accessories are required to reduce signal loss, reduce noise, and provide protection to the transmission line.

2. Medium Power AM Broadcast Station: For medium power AM broadcast stations, a standard 50 ohm 1-5/8 inch or 3-inch rigid coaxial transmission line is commonly used. These cables are designed to handle moderate power outputs ranging between 5 and 50 kilowatts. The connectors used in this case could be UHF, N-Type or EIA flange connectors.

3. High Power AM Broadcast Station: For high power AM broadcast stations, a rigid coaxial transmission line must be chosen which is capable of handling high power outputs exceeding 50 kilowatts. Cables used for high-power AM broadcast applications include 4-1/16 inch or 6-1/4 inch rigid coaxial lines with impedance matching transformers. These cables have a lower signal loss and can handle higher power levels than smaller cables. The connectors used in this case could be N-Type or EIA flange connectors.

The power handling capacity of the chosen cable is critical when selecting a rigid coaxial transmission line for an AM broadcast station. Signal loss is also an essential factor to consider since signal degradation can occur over longer cable runs. Careful selection of connectors and accessories is also needed to prevent problems such as interference and signal leakage.

Other factors to consider when selecting a rigid coaxial transmission line for an AM broadcast station are the length of the line and the frequency range. The length of the cable should be kept to a minimum to reduce signal loss. Rigid coaxial transmission lines with a lower characteristic impedance, such as 50 ohms, are often preferable for AM broadcast applications. Signal impedance matching is also important to ensure that the signal transmission is optimal.

Accessories for a rigid coaxial transmission line may include jumper cables, connectors, surge arrestors, grounding kits, lightning arrestors, and termination blocks. These accessories are required to ensure proper installation, signal quality, and signal protection.

Overall, choosing a suitable rigid coaxial transmission line for an AM broadcast station is crucial for excellent signal quality and station reliability. The choice of cable, connector types, and accessories will depend on the power handling capacity, length, and frequency range of the system. It is highly recommended that an experienced RF engineer be consulted to ensure optimal performance of the AM broadcast station.

- How to choose the best rigid coaxial transmission lines for TV broadcast station?

- When selecting a rigid coaxial transmission line and accessories for a TV broadcasting station, several factors must be considered, such as power output, frequency range, line length, connector type, and required accessories.

1. Low Power TV Broadcast Station: For low power TV broadcast stations with power outputs up to 10 kilowatts, a 7/8 inch or 1-5/8 inch rigid coaxial transmission line with an impedance of 50 ohms can be used. These cables offer lower power handling capacity than larger cables but are more affordable and suitable for short cable runs. The connectors used in this case could be commonly available connector types such as BNC or N-Type.

2. Medium Power TV Broadcast Station: For medium power TV broadcast stations with power outputs up to 100 kilowatts, a 3-inch or 4-inch rigid coaxial transmission line with an impedance of 50 ohms is commonly used. These cables offer low signal loss, high reliability, and power handling capacity, making them suitable for medium to high power TV broadcasting systems. The connectors used in this case could be UHF, N-Type, or EIA flange connectors.

3. High Power TV Broadcast Station: For high power TV broadcast stations with power outputs exceeding 100 kilowatts, a 6-1/8 inch or 9-3/16 inch rigid coaxial transmission line is commonly used. These cables offer low signal loss, high reliability, and power handling capacity, making them suitable for high-power TV broadcasting systems. The connectors used in this case are typically N-Type or EIA flange connectors.

The length of the cable needed will depend on the specific requirements of the TV broadcasting station. Lower loss coaxial cables are ideal for longer cable runs since signal loss is an essential factor to consider. The frequency range for TV broadcasting systems generally operates around VHF and UHF bands, requiring a higher impedance coaxial cable.

Accessories for a rigid coaxial transmission line may include jumper cables, connectors, surge arrestors, grounding kits, lightning arrestors, and termination blocks. These accessories are required to ensure proper installation, signal quality, and signal protection.

The cable options mentioned in the previous answer for TV broadcasting system can also be applied for UHF and VHF broadcasting stations. However, the ideal cable choice will depend on the specific requirements of the UHF or VHF system.

UHF broadcasting typically operates above 300 MHz, while VHF broadcasting operates typically between 30 MHz and 300 MHz. Cable selection for UHF or VHF broadcasting will depend on the specific frequency range of the system and the desired level of power output. For example, a lower power UHF or VHF broadcasting system may require a smaller cable with lower power handling capacity, while a high power system will require a larger cable with higher power handling capacity.

Overall, when selecting a rigid coaxial transmission line for a TV broadcasting station, the critical factors are the frequency range, power handling capacity, length, and accessories. Choosing the appropriate cable and accessories will ensure that the station performs well and provides reliable signal quality. It is highly recommended that an experienced RF engineer be consulted to ensure optimal performance of the TV broadcasting station.

- What are advantages and disadvantages of using rigid coaxial transmission lines?

- Advantages:

1. Low Attenuation: Rigid coaxial transmission lines offer low attenuation, which means that the signal loss during transmission is minimal. This is particularly advantageous in systems where long cable runs are necessary.

2. High Power Handling Capacity: Rigid coaxial transmission lines can handle high power levels, making them well-suited for high-power transmission applications like broadcasting.

3. Low Signal Interference: The shielded design of rigid coaxial transmission lines helps to minimize the interference from external sources, which is essential for maintaining signal quality and consistency.

4. High Reliability: Due to their robust design, rigid coaxial transmission lines are highly reliable and can withstand harsh environmental conditions.

5. Wide Frequency Range: Rigid coaxial transmission lines can operate across a wide range of frequencies and are therefore versatile for use in different types of RF communication systems.

Disadvantages:

1. Limited Flexibility: Rigid coaxial transmission lines are physically rigid and do not bend or flex easily, which can make installation challenging in tight or awkward spaces.

2. High Cost: Rigid coaxial transmission lines are generally more expensive than flexible coaxial cables and other types of transmission lines.

3. Challenging Installation: The installation of rigid coaxial transmission lines may be more challenging than other types of transmission lines, requiring specialized equipment and trained technicians.

4. Large Size: The physical size of rigid coaxial transmission lines can be quite large, which may limit their suitability for certain applications.

Overall, the advantages of using a rigid coaxial transmission line, such as low attenuation and high power handling capacity, make them well-suited for use in broadcasting applications like UHF broadcasting, VHF broadcasting, FM broadcasting, AM broadcasting, and TV broadcasting. However, their limited flexibility, high cost, and challenging installation may make them more suitable for specific applications where their advantages outweigh their disadvantages.

- What are common types of rigid coaxial transmission lines for radio broadcasting?

- There are several types of rigid coaxial transmission lines used in RF communication for radio broadcasting:

- 1/2 inch Rigid Coaxial Transmission Line: This type of cable is well-suited for low to medium power applications in the frequency range of 0 to 500 MHz. It has a maximum power handling capacity of around 4 kW and is relatively affordable. Its connector types are usually BNC and N-type.

- 7/8 inch Rigid Coaxial Transmission Line: This type of cable is ideal for medium to high power UHF broadcasting system. It has a maximum power handling capacity of around 12 kW and can be used for frequencies ranging from 0 to 2 GHz. Its connector types are usually BNC, N-type, and DIN.

- 1-5/8 inch Rigid Coaxial Transmission Line: This type of cable is commonly used in high power applications when the power output exceeds 100 kW. Its maximum power handling capacity is up to 88 kW and it can operate in frequencies up to 1 kHz. The connectors used are usually DIN and EIA flange.

- 3-1/8 inch Rigid Coaxial Transmission Line: This type of cable is used for extremely high power applications, typically greater than 1 MW. It has a maximum power handling capacity of up to 10 MW and is suitable for frequencies up to 500 MHz. The connectors used are usually EIA flange and DIN.

- 4-1/16 inch Rigid Coaxial Transmission Line: This type of cable is commonly used in medium to high power applications that require a large diameter cable but are not extreme as 1-5/8 and 3-1/8 inch cables. It can operate for frequencies up to 500 MHz and can handle a maximum power output of 80 kW. The connectors used are usually EIA flange and DIN.

- 6-1/8 inch Rigid Coaxial Transmission Line: This type of cable is best suited for high power applications, typically beyond 10 kW. It has a maximum power handling capacity of up to 44 kW and can be used for a frequency range of up to 500 MHz. The connectors used are typically EIA flange and DIN.

- 10-3/4 inch Rigid Coaxial Transmission Line: This type of cable is used for extremely high power applications, typically greater than 5 MW. It has a maximum power handling capacity of up to 30 MW and is suitable for frequencies up to 250 MHz. The connectors used are usually EIA flange and DIN. This large size cable is often used for long-distance transmission or when a large number of transmitters are connected to a single antenna.

- 1-1/4 inch Rigid Coaxial Transmission Line: This type of cable is commonly used in medium to high power applications that require a diameter between that of the 7/8 inch and 1-5/8 inch cables. It can handle a maximum power output of up to 25 kW and can be used for frequencies up to 2 GHz. The connectors used are usually BNC, N-type, and DIN.

- 5-1/8 inch Rigid Coaxial Transmission Line: This type of cable is used for very high power applications, typically greater than 1 MW. It has a maximum power handling capacity of up to 18 MW and can be used for frequencies up to 250 MHz. The connectors used are usually EIA flange and DIN.

- 9-3/16 inch Rigid Coaxial Transmission Line: This type of cable is used for very high power applications, typically greater than 4 MW. It has a maximum power handling capacity of up to 25 MW and can be used for frequencies up to 250 MHz. The connectors used are usually EIA flange and DIN.

- 8-3/16 inch Rigid Coaxial Transmission Line: This type of cable is used for very high power applications, typically greater than 3 MW. It has a maximum power handling capacity of up to 15 MW and can be used for frequencies up to 250 MHz. The connectors used are usually EIA flange and DIN.

- 12-3/4 inch Rigid Coaxial Transmission Line: This type of cable is used for extremely high power applications, typically greater than 7 MW. It has a maximum power handling capacity of up to 60 MW and can be used for frequencies up to 250 MHz. The connectors used are usually EIA flange and DIN.

In terms of power handling capacity, the larger the diameter of the cable, the higher the maximum power handling capacity. Rigid coaxial transmission lines are typically made of copper, which offers excellent electrical conductivity and durability.

The cost of each type of cable varies depending on the size, power handling capacity, and other specifications. Generally, larger cables and higher power handling capacities are more expensive.

Installation of rigid coaxial transmission lines requires specialized equipment and trained technicians due to their physical rigidity and the need for precise connections. Other equipment needed during installation may include connectors, grounding kits, surge arrestors, lightning arrestors, and termination blocks.

Overall, the choice of cable size and type will depend on the specific requirements of the broadcasting system in terms of power output, frequency range, and other factors. It is important to consult with a qualified RF engineer to determine the best type of cable for the application.

- What are common rigid coaxial transmission line for broadcasting transmitters?

- The selection of the best rigid coaxial transmission line for RF communication in different broadcasting applications depends on a variety of factors, including frequency range, power output, and location/terrain in which the broadcasting system will operate. Here are some general guidelines for different broadcasting applications:

1. UHF Broadcasting: For UHF broadcasting systems, the 7/8 inch or 1-5/8 inch rigid coaxial transmission line is commonly used, depending on the power output required. The 7/8 inch cable is ideal for low to medium power applications, while 1-5/8 inch cable is more suitable for high power applications. Both of these cables can handle high-frequency ranges.

2. VHF Broadcasting: For VHF broadcasting systems, the 1/2 inch rigid coaxial transmission line is often used for low to medium power applications. The 7/8 inch cable may also be used for medium to high power applications.

3. FM Broadcasting: For FM broadcasting systems, the 1-5/8 inch rigid coaxial transmission line is commonly used due to its high power handling capacity and frequency range.

4. AM Broadcasting: For AM broadcasting systems, a loop antenna is often used, and a different type of transmission line called the open-wire line is used instead of a rigid coaxial transmission line. Open-wire line is a balanced transmission line and has a different structure than rigid coaxial transmission lines.

5. TV Broadcasting: For TV broadcasting systems, the 3-1/8 inch or 6-1/8 inch rigid coaxial transmission line is often used due to the high power output required for TV broadcasting. The 4-1/16 inch Rigid Coaxial Transmission Line may also be used.

The cost and installation requirements of the rigid coaxial transmission line vary depending on the type of cable. In addition, the selection of connectors will depend on the specific needs of the broadcasting system and may include popular types such as BNC, N-type, DIN, and EIA flange.

Overall, the selection of the best rigid coaxial transmission line will depend on the specific requirements of the broadcasting application in terms of frequency range, power output, and other factors. It is recommended to consult with an experienced RF engineer to determine the best type of cable for a specific broadcasting system.

- How to correctly install an rigid coaxial transmission line for broadcasting stations?

- The installation of rigid coaxial transmission lines used in RF communication along with other broadcast components or equipment for broadcasting stations can be a complex process and requires careful attention to detail. Here are the general steps to properly install a rigid coaxial transmission line:

1. Plan the installation: Before installing a rigid coaxial transmission line, it is important to plan the installation process. This involves determining the location of the transmission line, identifying any potential obstacles or hazards, and calculating the length of the cable required.

2. Prepare the equipment and tools: After planning the installation, the necessary equipment and tools should be gathered. This may include the rigid coaxial transmission line itself, connectors, grounding kits, clamps, and specialized tools such as torque wrenches, cable cutters, and crimping tools.

3. Install connectors: Connectors should be installed on both ends of the cable. This is typically done using specialized tools and ensuring that the connectors are properly seated and tightened to the specified torque.

4. Grounding: Grounding is a critical part of the installation process, which helps to protect against voltage surges and lightning strikes. Grounding kits should be installed on both the outer and inner conductors of the cable.

5. Cable routing and mounting: The cable should be routed and mounted in a manner that minimizes signals interference and mechanical stress. It is important to avoid sharp bends and kinks in the cable, which can damage the structure of the cable and degrade signal quality.

6. Test the installation: After the installation is complete, it is important to test the system for functionality and ensure that it meets the required specifications. Testing should involve analyzing signal quality, power output, and other relevant parameters.

During the installation process, there are some important considerations to keep in mind:

- Safety: Installation of rigid coaxial transmission line can be dangerous, especially for larger cables. Care should be taken to avoid injury or damage to the equipment.

- Proper cable handling: Rigid coaxial transmission line should be handled with care during the installation process, as the structure may be fragile and prone to damage.

- Connector Compatibility: Choosing connectors that are compatible with each other is very important for the installation. A mismatch between the cable and connector could result in signal degradation or system damage.

- Installation environment: The installation environment should also be taken into account, as extreme temperatures or weather conditions can affect the performance of the cable and may cause damage.

In summary, the installation of a rigid coaxial transmission line requires careful planning and attention to detail. Proper grounding, cable routing, and connector installation are critical to ensuring optimal system performance. It is recommended to work with an experienced RF engineer to design and install the system, and careful attention should be paid to safety measures to protect against injury or damage during the installation.

- What differs a RF coaxial cable, rigid coaxial transmission line and hardline coax?

- In radio broadcasting, there are three main types of coaxial cables used in RF communication: rigid coaxial transmission line, hardline coax, and RF coaxial cable.

Rigid Coaxial Transmission Line:

1. Coax Connectors Used: EIA flange, DIN

2. Size: Comes in various sizes, ranging from 1/2 inch to 12-3/4 inch in diameter

3. Advantages: Highly efficient, low signal loss, can handle high 4. power levels, can be used over long distances, and provides better performance at higher frequencies

5. Disadvantages: Expensive, difficult to install, and requires special machinery and expertise to terminate

6. Prices: High

7. Applications: Generally used for high-power applications in radio and television broadcast systems

8. Performance: Provides very low attenuation, can handle high power levels, and has low VSWR (Voltage Standing Wave Ratio)

9. Structure: For a rigid coaxial transmission line, the outer conductor is typically made of copper and it is not covered by any outer protective jacket. In some cases, a thin layer of paint or other protective coating may be applied to the outer conductor to protect against corrosion or other environmental factors, but this does not provide the same level of protection as an outer jacket on a flexible coaxial cable. Because rigid coaxial transmission lines are generally used in applications where a high-power, low-loss transmission path is required, such as in broadcasting, satellite communications, and military applications, they are not typically subject to the same environmental factors as flexible coaxial cables that may be used in outdoor or more rugged environments. However, designers must still consider any potential environmental factors that may affect the performance of a rigid coaxial transmission line, such as temperature changes or exposure to moisture or other contaminants.

10. Power Handling Capacity: Ranges from a few watts to several megawatts, depending on the size of the cable

11. Installation: Requires specialized expertise and equipment

12. Repairment: Repair may require replacing the damaged section of cable, which can be expensive

13. Maintenance: Regular cleaning and maintenance is required to keep the cable’s performance at an optimal level.

Hardline Coax:

1. Coax Connectors Used: N-type, UHF, or BNC connectors

2. Size: Typically ranges from 1/2 inch to 8-5/8 inch in diameter

3. Advantages: Provides good performance at a reasonable cost, relatively easy to terminate and install, and can be used for medium-to-high power applications

4. Disadvantages: Provides higher latency and lower performance at higher frequencies than rigid coaxial transmission line.

5. Prices: Mid-range

6. Applications: Used in a variety of applications, including antenna distribution, Wi-Fi transmission, radio broadcasting, and cable television

7. Performance: Provides moderate attenuation, medium power handling capacity, and moderate VSWR

8. Structure: Consists of a center conductor, a dielectric insulator, an outer conductor, and a jacket

9. Power Handling Capacity: Ranges from a few watts to several kilowatts, depending on the size of the cable

10. Installation: Requires specialized expertise and suitable equipment

11. Repairment: Repair may require replacing the damaged section of cable or replacing the cable entirely.

12. Maintenance: Requires periodic cleaning and maintenance to maintain performance.

Semi-rigid coaxial cable

Semi-rigid coaxial cable, also known as conformable cable, is a type of coaxial cable that falls somewhere between the flexibility of RF coaxial cable and the rigidity of hardline coax. It is typically constructed of a solid outer conductor and a strip-like inner conductor with a dielectric layer in between.

Here are some differences between semi-rigid coaxial cable and the previously discussed types of coaxial cables:

1. Coax Connectors Used: SMA, N-type or TNC connectors are commonly used.

2. Size: Semi-rigid coaxial cable is typically available in diameters between 0.034 inches to 0.250 inches.

3. Advantages: Semi-rigid coaxial cable has low attenuation, excellent shielding effectiveness, efficient power-handling capability and excellent phase stability. It also has a high degree of flexibility compared to rigid coaxial cable, which makes it easier to install.

4. Disadvantages: Semi-rigid coaxial cable has more loss (attenuation) than rigid coaxial transmission line, less power carrying capacity and less mechanical stability compared to hardline coaxial cable.

5. Prices: Semi-rigid coaxial cable is more expensive than RF coaxial cable but less expensive than hardline coaxial cable.

6. Applications: Semi-rigid coaxial cable is used in many applications such as military, aerospace, telecommunications, RF and microwave equipment and testing, instrumentation and medical equipment.

7. Performance: Semi-rigid coaxial cable offers low attenuation and high shielding effectiveness. It can handle power levels between RF coaxial cable and hardline coaxial cable and offers greater phase stability than other types of cables.

8. Structure: Semi-rigid coaxial cable has a solid outer conductor, dielectric spacer, and a strip-like inner conductor, similar to a coaxial hardline.

9. Power Handling Capacity: Semi-rigid coaxial cable can handle power levels ranging from a few watts to several kilowatts, depending on the size of the cable.

10. Installation: Semi-rigid coaxial cable is generally easier to install than rigid coaxial transmission line or hardline coaxial cable due to its greater flexibility, requiring fewer specialized tools.

11. Repairment: If the cable is damaged, sections of the cable can be replaced without the need for replacing the entire cable.

12. Maintenance: Periodic cleaning and maintenance are required to prevent damage and maintain performance.

RF Coaxial Cable:

1. Coax Connectors Used: BNC, F-type, N-type, TNC, SMA, etc.

Size: Typically ranges from 1/32-inch (RG-174) to 1-inch (RG-213) in diameter

2. Advantages: Easy to install, lower cost, and flexible

3. Disadvantages: Not suitable for high power transmission, provides higher latency, and larger signal loss than rigid coaxial transmission line and hardline coax.

4. Prices: Low to moderate

5. Applications: Commonly used in low-power RF and video applications, such as in CCTV systems, Wi-Fi, and shortwave radio.

6. Performance: Provides moderate attenuation, power-handling capacity and VSWR that varies with diameter, frequency, and cable quality

7. Structure: Consists of a center conductor, a dielectric insulator, a shielding conductor, and an outer jacket

8. Power handling capacity: Generally ranges from a few watts to around 1 kW, depending on cable diameter and frequency

9. Installation: Can be terminated with easy-to-use connectors, and is more flexible, thinner and easier to handle than hardline coax or rigid coaxial transmission line.

10. Repairment: Damaged sections of the cable can be replaced without replacing the entire cable.

11. Maintenance: Requires periodic cleaning and maintenance to maintain performance and prevent damage.

- What may fails an rigid coaxial transmission line from working?

- There are several situations, reasons, or inappropriate manual operating that may cause a rigid coaxial transmission line to fail in RF communication. Some of these include:

1. Overheating: Rigid coaxial transmission lines have the potential to overheat if too much power is running through them for an extended period of time, which can cause damage to the line.

2. Corrosion: Exposure to moisture and other contaminants can cause corrosion in the transmission line, which can weaken the line and reduce its efficiency.

3. Physical damage: Rigid coaxial transmission lines can be physically damaged by improper installation or handling. This can include bending the line beyond its designed specifications or subjecting it to excessive force.

4. Poor connections: Incorrectly installing or connecting the transmission line to the equipment or other cables can lead to signal loss or power imbalance.

To avoid these situations from happening, it is important to follow proper installation and operating procedures for the transmission line. This includes:

1. Ensuring that the transmission line is properly rated for the intended application and power level.

2. Properly grounding the transmission line to prevent electrical noise and interference.

3. Protecting the line from moisture and other contaminants by installing appropriate seals and covers.

4. Using appropriate tools and techniques when handling the transmission line to prevent physical damage.

5. Checking and rechecking connections to ensure a secure and proper fit.

- What is rigid line and how it works?

- A rigid line is a type of electrical cable used to transmit high-frequency signals over long distances. It is made up of a core conductor, an insulator, and a protective outer sheath. The core conductor is usually made of copper and is surrounded by a dielectric insulator, which is usually made of a polymer or fiberglass. The sheath is usually made of a metallic material, such as aluminum or steel, which provides electrical shielding and protection from the environment. Rigid lines are important because they can transmit signals with greater accuracy and efficiency than traditional cables. They are also more resistant to signal loss due to external electromagnetic interference. This is because the rigid structure prevents the signal from being distorted or attenuated by outside sources. Additionally, rigid lines are more resistant to physical damage caused by weather and other environmental factors.

- What are the applications of rigid line?

- rigid lines are used in a variety of applications including power transmission, data transmission, microwave communication, and more. The most common applications are power transmission, data transmission, and RF (Radio Frequency) communication. In power transmission, rigid lines are used to transmit electricity from one point to another. This includes power lines, substations, and distribution networks. In data transmission, rigid lines are used to transmit signals such as internet and voice signals. Finally, in RF communication, rigid lines are used to transmit electromagnetic radiation or radio waves. They are used in broadcast towers, cellular towers, and other wireless communication systems.

- How to correctly use rigid line for broadcasting?

- Steps to properly using rigid lines for a broadcast radio station:

1. Choose the appropriate type of line for the broadcast, based on the power and range of the station.

2. Ensure that the line runs in a straight line and is not kinked or bent.

3. Install the line in a way that minimizes wind and ice loading.

4. Connect the line to the antenna and transmitter with the correct fittings.

5. Monitor the line regularly to make sure it is in good condition and that there are no signs of damage.

Problems to avoid:

1. Avoid kinks or bends in the line, as this can cause a decrease in performance.

2. Avoid running the line too close to other sources of interference, such as power lines.

3. Avoid running the line too close to the ground, as this can cause ground losses.

4. Avoid having too much power running through the line, as this can cause overheating and damage.

- What determines the performance of rigid line and why?

- The performance of a rigid line is determined by the characteristics of its materials, such as its electrical conductivity, dielectric constant, and inductance. These characteristics are important because they affect the transmission line’s ability to transfer signals from one point to another without distortion or interference. Additionally, the physical configuration of the transmission line also affects its performance, such as the number of turns, the length of the line, and the spacing between turns.

- What is a rigid line consists of?

- A rigid line consists of several components, parts and accessories. The main components include a transmission line conductor, insulators, a ground wire, and a metallic shield.

The conductor is the main component of a rigid line and is responsible for carrying the current. It is usually made of copper, aluminum or other highly conducting material. The conductor’s diameter and wire gauge must be carefully chosen to ensure that it can safely transmit the required voltage and current.

Insulators are used to maintain the electrical field between the conductor and the ground wire. Insulators are usually made of ceramic, rubber, plastic or other non-conducting material.

The ground wire is used to provide a path for the current to flow back to the source. It is usually made of copper, aluminum or other highly conducting material.

The metallic shield is used to protect the insulated transmission line from electromagnetic interference. It is typically made of an aluminum or other metallic material with a high permeability.

When selecting components for a rigid line, it is important to consider the operating voltage and current, frequency, and temperature range. Additionally, the components must be chosen to ensure that they are compatible with each other, and that the transmission line meets the desired electrical and mechanical requirements.

- How many types of rigid line are there?

- There are two types of rigid lines: coaxial cables and waveguides. Coaxial cables are primarily used to carry high frequency electrical signals, while waveguides are designed to carry electromagnetic energy at radio frequencies. The main difference between the two is that coaxial cables have an inner conductor surrounded by an outer conductor, while waveguides have an inner conductor surrounded by a dielectric material, such as glass or plastic. In addition, waveguides are typically larger and can carry higher power than coaxial cables.

- How to choose the best rigid line?

- When choosing the best rigid line for a broadcast radio station, it is important to consider the power level and frequency of the station, the antenna type and the local environment. Additionally, it is important to review the manufacturer's specifications for the transmission line and the available warranties, as well as the overall cost and installation considerations.

- How to correctly connect a rigid line in a transmission site?

- To correctly connect a rigid line in a broadcast radio station, you should start by making sure that the transmission line is properly grounded. Next, you should connect the transmission line to the radio station's antenna system. You should also check to make sure that the line is properly matched to the antenna system. Finally, you should connect the transmission line to a power amplifier and adjust the radio station's transmitter to the correct frequency.

- What are the most important specifications of a rigid line?

- The most important physical and RF specifications of a rigid line are: impedance, electrical length, insertion loss, and return loss. Other characteristics to consider include the temperature coefficient, temperature range, operating frequency range, and maximum voltage standing wave ratio (VSWR).

- How to maintain a rigid line in a transmission site?

- To correctly perform daily maintenance of a rigid line in a radio station as an engineer, you should start by visually inspecting the rigid line for any signs of damage, corrosion, or wear. You should also ensure that all connections are properly tightened and all clamps are secure. After inspecting the line, you should then check the transmission line for any changes in electrical parameters such as input power, VSWR, and return loss. Finally, you should verify the antenna radiation pattern to ensure that it is aligned correctly and operating within specifications.

- How to repair a rigid line if it fail working?

- 1. Inspect the transmission line for any signs of damage or wear. Check for any broken or loose parts, frayed wires, or bent connectors.

2. Replace any broken or worn parts with new ones. Make sure the new parts are the same size and shape as the old ones.

3. Clean the transmission line with a degreaser and a soft cloth.

4. Reassemble the transmission line, ensuring all parts are tightened securely.

5. Test the transmission line to ensure it is functioning correctly.

6. If the transmission line fails to work, check for any additional problems such as an air leak or a short in the line. Replace any additional parts as necessary.

- What types of connectors are used for a rigid line?

- Types of connectors used for rigid transmission lines include crimp-on and soldered connectors. Crimp-on connectors are typically made from copper or aluminum and require the use of a crimping tool to press the connector onto the line. Soldered connectors are typically made from copper or tin and require a soldering iron and solder to attach the connector to the line. There are several different types of crimp-on and soldered connectors available, including compression connectors, twist-on connectors, spade lugs, and butt connectors. Each type has its own unique advantages and disadvantages. The number of types of each type of connector depends on the specific application and requirements.

CONTACT US

FMUSER INTERNATIONAL GROUP LIMITED.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us