Fiber Optic Cables

What is a Fiber Optic Cable and How it Works?

Fiber optic cable is a high-speed communication medium that utilizes thin strands of optically pure glass or plastic to transmit data as pulses of light. These cables are designed to carry vast amounts of information over long distances, enabling fast and reliable communication across various applications. Operating on the principle of total internal reflection, these cables have a central core made of glass or plastic, surrounded by cladding with a lower refractive index. This structure ensures that light signals entering the core undergo repeated internal reflections, allowing them to travel over long distances with minimal signal loss. This fundamental design provides the foundation for the exceptional speed, bandwidth, reliability, and security offered by fiber optic cable in modern telecommunication systems.

Tailored Fiber Optic Cable Solution from FMUSER

At FMUSER, we're on a mission to revolutionize the telecommunication market with our exceptional range of end-to-end cable products and service solutions. With a steadfast focus on innovation and customer satisfaction, we provide the backbone for seamless connectivity across various industries and applications.

Factory Price: Cost-Effective Solutions for Your Budget

At FMUSER, we believe in providing cost-effective solutions without compromising on quality. Our commitment to offering factory prices ensures that our customers receive the best value for their investment.

By eliminating unnecessary intermediaries and working directly with our manufacturing facilities, we can offer competitive pricing while maintaining the highest standards of performance, reliability, and durability. With FMUSER, you can trust that you're getting top-notch fiber optic cables at a price that suits your budget.

In-stock & Ship the Same Day: Swift Delivery to Meet Your Deadlines

We understand the importance of timely project completion and meeting deadlines. That's why FMUSER maintains a robust inventory of our most popular fiber optic cable products. With our in-stock items, we can expedite the shipping process, allowing us to deliver your order promptly. When you choose FMUSER, you can rest assured that your fiber optic cables will be shipped the same day, ensuring efficient project management and reduced downtime. We prioritize your needs, providing a seamless experience from order placement to delivery.

By coupling our factory pricing with swift shipping, FMUSER ensures that you not only receive cost-effective solutions but also enjoy a streamlined procurement process. With FMUSER, you can confidently meet your project timelines and budgetary requirements, all while benefiting from high-quality fiber optic cables that empower your communication infrastructure.

Customization at its Finest: FMUSER's Tailored Fiber Optic Cable Solutions

At FMUSER, we understand that every project has unique requirements. That's why we offer customization options that allow you to tailor fiber optic cables to your specific needs.

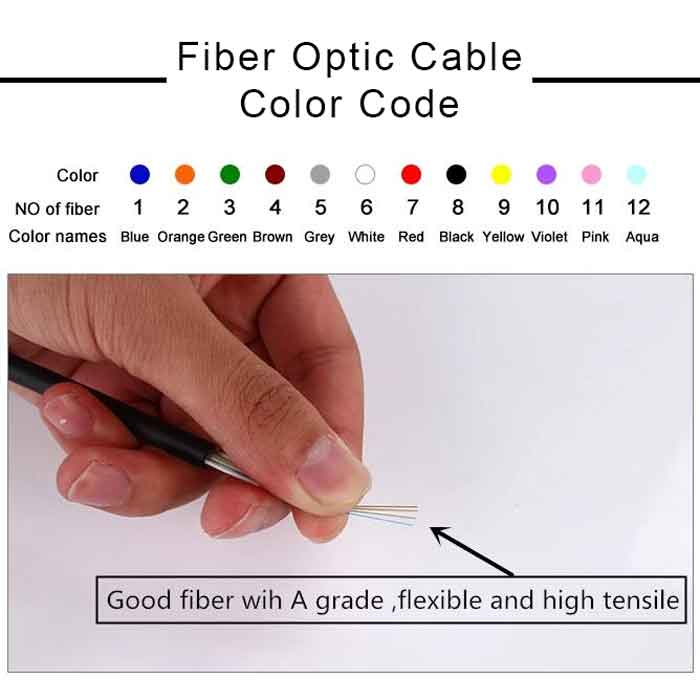

With a global presence in over 138 countries, our products span an impressive 12,000,000 km. With an annual production capacity exceeding 3.5 million kilometers, FMUSER is the specialist in outdoor optic fiber cables, catering to the diverse needs of optical communication systems worldwide. Whether you require specialized cable designs, specific lengths, or custom connectors, we provide solutions that align perfectly with your project objectives. Our dedicated team of experts works closely with you to ensure that the final product meets your exact specifications, guaranteeing optimal performance and reliability.

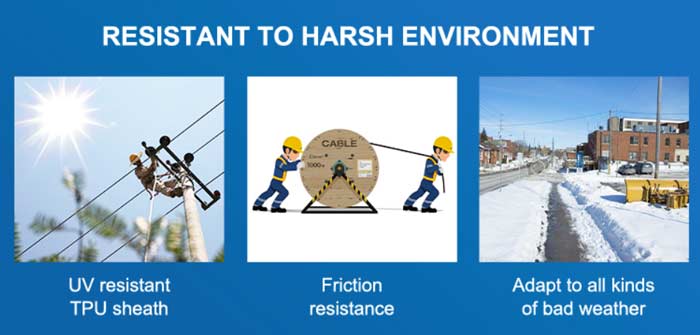

Our cables are specifically designed to withstand harsh environmental conditions and offer excellent resistance to factors such as moisture, temperature variations, and physical damage. You can count on our comprehensive cable solutions to meet your specific requirements, delivering reliable performance and durability in any setting.

Additionally, whether you need single-mode (including 850nm, 1300nm, and 1550nm) or multimode fiber optic cables, our extensive range offers different core diameters and bandwidth capabilities, allowing you to choose the most suitable option for your application.

Connector Types & Polishing: Highly Precision for Seamless Connectivity

When it comes to fiber optic cable connectors, precision and reliability are paramount. FMUSER offers a wide range of connector types to suit various applications, including ST, SC, and LC connectors, among others.

Our connectors undergo meticulous polishing processes, ensuring low insertion loss and high return loss for seamless and efficient connectivity. With our commitment to precision engineering, you can rely on FMUSER's connectors to deliver exceptional performance and maintain signal integrity throughout your network.

Through our commitment to customization, precision, and tailored solutions, FMUSER ensures that your fiber optic cable deployment perfectly aligns with your project's unique demands. With FMUSER as your trusted partner, you can confidently connect your business to the future of communication technology.

Turnkey Fiber Optic Cables Options

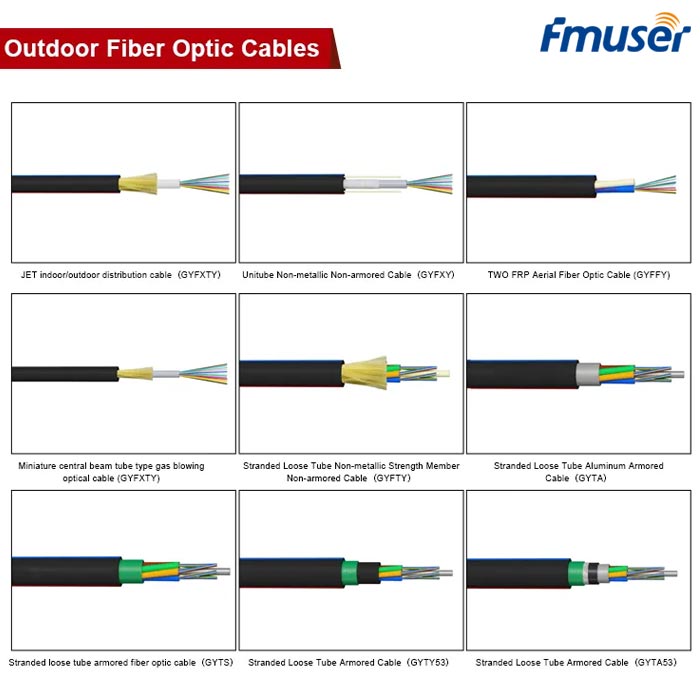

Our product portfolio encompasses a wide range of cutting-edge fiber optic cables, designed to meet the diverse needs of our customers.

Our Best-selling Fiber Optic Cables

|

|

|

|

| Hybrid Fiber | GYFTY Fiber | GYTA/GYTS Fiber | GYFTA53 Fiber |

|

|

|

|

| ADSS Fiber | GYTC8A Fiber | JET Fiber | GYXS/GYXTW Fiber |

|

|

|

|

| GJYXFHS Fiber | GJXFA Fiber | GJXFH Fiber | GJYXFCH Fiber |

Whether you require layer stranded optical cables, central-tube optical cables, ribbon optical cables, special optical cables, indoor optical cables, or power optical cables, FMUSER has you covered. We have invested extensively in research and development to ensure that our products exceed industry standards and deliver unmatched performance.

General outdoor optical cables

- Duct and Non-Self Supporting Aerial Cable

- Direct buried Cable

- All Dielectric Self-supporting Aerial Optical Fiber Cable

- Ribbon Optical Fiber Cable

- FIG 8 Self-supporting Aerial Optical Fiber Cable

- Shallow Water Optical Fiber Cable

Indoor optical cables

- Jumper wire

- Indoor Cabling System

- FTTX Drop Cable

- Indoor Multi-fiber Riser Cable

- MPO Jumper Wire

Recommended Fiber Patch Cords In Stock & Ship the Same Day:

|

|

|

|

|

|

|

|

|

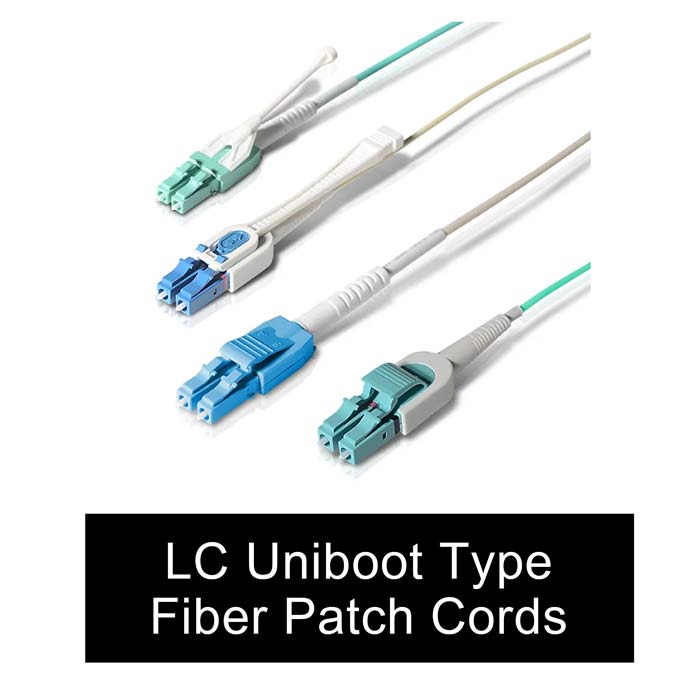

| LC Uniboot Fiber Patch Cords Series | MTRJ Fiber Patch Cords Series | SMA Fiber Patch Cords Series |

Special outdoor optical cables

- All Dielectric Reinforced Optical Fiber Cable

- U-Tube Air-Blowing Micro Optical Fiber Cable

- Drainage Pipe Optical Fiber Cable

- All Dielectric Self-supporting Drop Cable

- Optical and Electrical Hybrid Cable for Access Network

- Anti-rodent Optical Fiber Cable

- A-Dry Type Optical Fiber Cable

- Flame-retardant Optical Fiber Cable

- Groove Optical Fiber Cable

- Easily recognized Optical Fiber Cable

- High Flame-retardant And Fire-resistant Cable

To maintain our commitment to excellence, we have established state-of-the-art facilities including standard air-blowing proving grounds and flame retardant/fire-resistant combustion laboratories. These facilities adhere to the rigorous GB/T and IEC standards, ensuring the highest quality and reliability of our products. Furthermore, our dedication to quality has been recognized through our CNAS certification, solidifying our position as a trusted leader in the industry.

One of our proudest achievements is the successful development of Ultra-fine Air-dry Optical Cables, All-dry ADSS Optical Cables, Anti-bite Optical Cables, and other ground-breaking products. These innovations have found widespread applications in diverse scenarios, earning us a loyal customer base not only in America, Europe, and the Middle East but also across the globe.

Best Indoor & Ourdoor Fiber Cable Solutions

FMUSER's fiber optic cables are highly versatile and find extensive applications across a wide range of industries. Let's explore the two main categories: indoor and outdoor, where our cables excel. Additionally, we'll highlight an additional application where our fiber optic cables deliver exceptional performance.

Indoor Applications: Enabling Efficient Connectivity

FMUSER's fiber optic cables are perfectly suited for indoor applications, providing efficient connectivity solutions. These applications include:

- Telecommunications and Data Centers: Our fiber optic cables offer high-speed and reliable communication for telecommunications networks and data centers, facilitating seamless data transmission and ensuring efficient connectivity for voice, video, and data services.

- Educational Institutions and Office Buildings: FMUSER's fiber optic cables enable fast and secure communication within educational institutions and office buildings, supporting high-bandwidth applications such as video conferencing, cloud services, and data sharing.

- Healthcare Facilities: Our cables facilitate quick and secure transmission of medical records, imaging data, and telemedicine services, ensuring uninterrupted connectivity and efficient healthcare delivery.

Outdoor Applications: Extending Communication Networks

When it comes to outdoor optic fiber cable systems, FMUSER stands as a renowned global manufacturer, providing comprehensive solutions for telecommunication applications worldwide. With a rich heritage in advanced research and development, we harness cutting-edge technology to deliver tailor-made fiber optic cable solutions.

FMUSER's fiber optic cables are designed to withstand harsh outdoor environments, making them ideal for various outdoor applications. These applications include:

- Telecommunication Networks: Our cables play a crucial role in expanding telecommunication networks, providing reliable connectivity for long-distance communication, including fiber-to-the-home (FTTH), 5G networks, and broadband services.

- Utility and Power Infrastructure: FMUSER's fiber optic cables are used in power utility applications, facilitating efficient monitoring and control of power grids, smart metering, and remote sensing for improved energy management and distribution.

- Transportation and Traffic Management: Our cables enable real-time communication and data transmission for transportation systems, including railway networks, traffic control systems, and intelligent transportation systems (ITS), ensuring smooth operations and enhancing safety.

By catering to diverse indoor & outdoor applications, FMUSER's fiber optic cables offer the flexibility, reliability, and performance required to meet the demands of various industries. With FMUSER as your partner, you can confidently deploy fiber optic cable solutions that enhance connectivity and drive innovation within your specific application area.

We extend a warm welcome to customers from all corners of the globe to visit us and explore the possibilities of a long-term partnership. At FMUSER, we strive to meet your every need and exceed your expectations, ensuring seamless connectivity for a connected future.

-

![Hybrid Fiber Copper Cable for Efficient Data & Power Transmission (Aerial, Pipeline, Direct-buried, etc.)]()

Price(USD):Ask for a quotation

Sold:14

-

![GYFTY: Non-armored Outdoor Fiber Optic Cable with Stranded Loss Tube & FRP Member]()

GYFTY: Non-armored Outdoor Fiber Optic Cable with Stranded Loss Tube & FRP Member

Price(USD):Ask for a quotation

Sold:14

-

![GYTS/GYTA Light-armored Outdoor Fiber Optic Cable (SPS/APL Coated) with Central Strength Member]()

GYTS/GYTA Light-armored Outdoor Fiber Optic Cable (SPS/APL Coated) with Central Strength Member

Price(USD):Ask for a quotation

Sold:14

-

![GYFTA53 Outdoor Fiber with Looss Tube & FRP Member for Underground (Diret Buried)]()

GYFTA53 Outdoor Fiber with Looss Tube & FRP Member for Underground (Diret Buried)

Price(USD):Ask for a quotation

Sold:14

-

![ADSS: All Dielectric Self-supporting Aerial Fiber Optic Cable for Outdoor Network]()

ADSS: All Dielectric Self-supporting Aerial Fiber Optic Cable for Outdoor Network

Price(USD):Ask for a quotation

Sold:14

-

![GYTC8A: Figure 8 Cable Sefl-supporting Fiber Optic Cable Up to 60 Fiber Cores]()

GYTC8A: Figure 8 Cable Sefl-supporting Fiber Optic Cable Up to 60 Fiber Cores

Price(USD):Ask for a quotation

Sold:14

-

![JET Fiber: Non-Metallic Miniature Fiber Optical Cable for Backbone & Access Network]()

JET Fiber: Non-Metallic Miniature Fiber Optical Cable for Backbone & Access Network

Price(USD):Ask for a quotation

Sold:14

-

![GYXS/GYXTW Outdoor Fiber Optic (Tube-core & Light Armor Design)]()

GYXS/GYXTW Outdoor Fiber Optic (Tube-core & Light Armor Design)

Price(USD):Ask for a quotation

Sold:14

-

![GJYXFHS: 7.4mm Bow-type Indoor Moisture-proof Fiber with Coated Steel Strip & Water-blocking Tape for Pipeline]()

Price(USD):Ask for a quotation

Sold:14

-

![GJXFA: 5mm Indoor Fiber with Inner & Outer LSZH Jacket and Strength Member (Steel/FRP)]()

GJXFA: 5mm Indoor Fiber with Inner & Outer LSZH Jacket and Strength Member (Steel/FRP)

Price(USD):Ask for a quotation

Sold:14

-

![GJXFH: Indoor Fiber Optic Cable with 1/2 Core & LSZH Jacket & 2 Strength Members (No Self-supporting))]()

Price(USD):Ask for a quotation

Sold:14

-

![GJYXFCH: Self-supporting Indoor Fiber Optic Cable with 1/2 Core & LSZH Jacket & 2 Strength Members]()

GJYXFCH: Self-supporting Indoor Fiber Optic Cable with 1/2 Core & LSZH Jacket & 2 Strength Members

Price(USD):Ask for a quotation

Sold:14

-

Advantages of fiber optic over traditional copper cables?

-

Fiber optic cables offer numerous advantages over traditional copper cables, making them a popular choice for modern communication networks. Here are some of the key advantages of using fiber optic cables:

- Faster Data Transfer Speeds: Fiber optic cables have a much higher bandwidth capacity compared to copper cables. They can transmit data at significantly faster speeds, allowing for greater amounts of data to be transferred in shorter periods of time. This attribute is particularly crucial for applications that require high-speed data transfer, such as video streaming, cloud computing, and large file transfers.

- Longer Transmission Distances: Fiber optic cables can transmit data over much greater distances without experiencing signal degradation. Copper cables, on the other hand, suffer from signal loss and attenuation over longer distances. With fiber optic cables, data can be transmitted over several kilometers without requiring signal regeneration or amplification, making them ideal for long-haul communication networks.

- Higher Bandwidth Capacity: Fiber optic cables have a significantly higher bandwidth capacity compared to copper cables. This means they can carry a much greater volume of data simultaneously. With the increasing demand for data-intensive applications, such as high-definition video streaming, virtual reality, and teleconferencing, fiber optic cables can handle the high bandwidth requirements more effectively.

- Immunity to Electromagnetic Interference: One of the major advantages of fiber optic cables is their immunity to electromagnetic interference (EMI). Copper cables are susceptible to EMI from nearby power lines, electrical equipment, and other cables. Fiber optic cables, being made of glass or plastic, are not affected by EMI. This makes them highly reliable in environments with high levels of electrical noise, such as manufacturing facilities or areas with heavy machinery.

- Thinner and Lighter: Fiber optic cables are much thinner and lighter compared to copper cables. This makes them easier to install and handle, especially in situations where space is limited. The reduced size and weight of fiber optic cables also make them more flexible and less prone to damage during installation or maintenance.

- Enhanced Security: Fiber optic cables offer a higher level of security compared to copper cables. Since they transmit data using light pulses, it is extremely difficult to tap into the signal without disrupting the transmission. This makes fiber optic cables more secure and less susceptible to unauthorized access or data interception.

- Future-Proof Technology: Fiber optic cables provide a more future-proof infrastructure compared to copper cables. The continuous advancements in fiber optic technology have consistently pushed the boundaries of data transmission speeds and capacity. While copper cables have limitations in terms of the maximum data rates they can support, fiber optic cables have the potential to meet the increasing demands of future technologies and applications.

In summary, fiber optic cables offer faster data transfer speeds, longer transmission distances, higher bandwidth capacity, immunity to electromagnetic interference, thinner and lighter form factor, enhanced security, and a future-proof solution for communication networks. These advantages make fiber optic cables an excellent choice for high-performance data transmission applications.

-

Bandwidth comparison: fiber optic vs. copper cables?

-

The bandwidth of fiber optic cables is significantly higher compared to copper cables. Bandwidth refers to the capacity of a communication channel to transmit data. Here's a detailed comparison of the bandwidth capabilities of fiber optic cables and copper cables:

Fiber Optic Cables:

Fiber optic cables have an incredibly high bandwidth capacity. They can transmit data at speeds measured in terabits per second (Tbps) or even higher. The bandwidth of fiber optic cables is primarily determined by the light signals they use for data transmission.

Fiber optic cables utilize pulses of light to transmit data. These light signals can travel through the fiber-optic cores with minimal loss or attenuation. This allows fiber optic cables to support a vast amount of data simultaneously.

Different types of fiber optic cables offer varying bandwidth capacities. Single-mode fiber (SMF) cables, which have a small core size and allow only a single mode of light to propagate, can provide the highest bandwidth capacity. They can support data transfer rates of up to 100 Gbps, 400 Gbps, or even higher.

Multimode fiber (MMF) cables, which have a larger core size and allow multiple modes of light to propagate, offer slightly lower bandwidth capacities compared to SMF. However, they can still support data rates ranging from 10 Gbps to 100 Gbps.

Copper Cables:

Copper cables, such as twisted-pair cables (e.g., Cat 5e, Cat 6, Cat 6a) and coaxial cables, have a lower bandwidth capacity compared to fiber optic cables. The bandwidth of copper cables is primarily limited by the electrical signals they use for data transmission.

The bandwidth of copper cables is determined by factors like the cable's length, wire gauge, and the presence of external interference. As data travels through copper cables, it experiences degradation due to various factors, including resistance, crosstalk, and electromagnetic interference.

Twisted-pair copper cables, commonly used in Ethernet networks, have limited bandwidth capacities. For example, Cat 5e cables can support data rates up to 1 Gbps, Cat 6 and Cat 6a cables can handle speeds up to 10 Gbps, and Cat 7 cables can support data rates up to 40 Gbps.

Coaxial cables, often used for cable television or broadband internet, offer higher bandwidth capabilities compared to twisted-pair cables. Depending on the specific type and quality, coaxial cables can support data rates ranging from 1 Gbps up to 10 Gbps or more.

Comparison:

When comparing the bandwidth of fiber optic cables and copper cables, fiber optic cables consistently offer significantly higher bandwidth capacity. Fiber optic cables can support data rates in the range of gigabits per second (Gbps) to terabits per second (Tbps), whereas copper cables typically have lower bandwidth capacities, usually measured in Gbps.

The higher bandwidth of fiber optic cables enables faster data transfer rates, making them more suitable for applications that require large amounts of data to be transmitted quickly, such as high-definition video streaming, cloud computing, and data-intensive research.

Overall, fiber optic cables provide a much wider bandwidth capacity, allowing them to handle more data simultaneously and support higher-speed communication networks compared to copper cables.

-

Max distance of fiber optic cables for data transmission without degradation?

-

Fiber optic cables can transmit data over long distances without experiencing significant signal degradation. The maximum distance that fiber optic cables can carry data without degradation depends on various factors, including the type of fiber, the transmission equipment used, and the data rate being transmitted. Here's a detailed explanation:

Single-Mode Fiber (SMF):

Single-mode fiber (SMF) is designed for long-haul communication and can transmit data over the longest distances without signal degradation. SMF has a small core size that allows only a single mode of light to propagate. The low attenuation and dispersion characteristics of SMF enable data transmission over much greater distances compared to multimode fiber.

With advanced amplification techniques and the use of high-quality components, SMF can transmit data for tens or even hundreds of kilometers without requiring signal regeneration or amplification. For example, modern SMF systems can transmit data over distances exceeding 100 kilometers (62 miles) without significant signal degradation.

Multimode Fiber (MMF):

Multimode fiber (MMF) has a larger core size compared to single-mode fiber and supports the propagation of multiple modes of light. MMF is commonly used for shorter-distance communication within buildings or campuses.

The maximum distance for data transmission without degradation in multimode fiber depends on the type of MMF and the data rate being used. Generally, the maximum distance for MMF ranges from a few hundred meters to a few kilometers.

For example, using 10 Gigabit Ethernet (10 Gbps) over OM3 or OM4 multimode fiber, the maximum distance is typically around 300 meters. With the latest advancements in multimode fiber technology and the use of more advanced modulation techniques, it is possible to achieve longer transmission distances up to 550 meters or even more.

It's important to note that the maximum distance supported by MMF can be significantly increased using mode conditioning patch cables or by implementing wavelength-division multiplexing (WDM) techniques.

Factors Affecting Distance:

Several factors can affect the maximum distance for data transmission without signal degradation in fiber optic cables:

- Attenuation: Attenuation refers to the loss of signal strength as it travels through the fiber. Fiber optic cables are designed to minimize attenuation, but it still increases with distance. Higher-quality fibers have lower attenuation, allowing for longer transmission distances without degradation.

- Dispersion: Dispersion is the spreading of light pulses as they travel through the fiber. Chromatic dispersion and modal dispersion can limit the maximum distance of data transmission. Advanced fibers and signal processing techniques are used to minimize dispersion effects.

- Transmitter and Receiver Quality: The quality and power of the optical transmitters and receivers also affect the maximum distance of data transmission. High-quality components can transmit and receive signals over longer distances with less degradation.

- Amplification and Regeneration: Optical amplifiers or regenerators can be used to boost the signal strength and extend the maximum transmission distance. These components amplify or regenerate the optical signal to compensate for losses.

- Wavelength and Data Rate: The wavelength used for transmission and the data rate being transmitted also impact the maximum distance. Different wavelengths and higher data rates may have shorter maximum distances due to increased attenuation or dispersion effects.

In summary, the maximum distance that fiber optic cables can transmit data without significant signal degradation depends on the type of fiber (single-mode or multimode), the specific fiber characteristics, the quality of the transmission equipment, and the data rate being transmitted. Single-mode fiber can support transmissions over longer distances, often exceeding 100 kilometers, while multimode fiber typically has maximum distances ranging from a few hundred meters to a few kilometers.

-

Indoor and outdoor use of fiber optic cables?

-

Fiber optic cables can indeed be used for both indoor and outdoor installations. The installation process and location may vary depending on the specific requirements of the installation. Here's a detailed explanation of how fiber optic cables are installed for indoor and outdoor applications:

Indoor Installations:

For indoor installations, fiber optic cables are typically routed within buildings, data centers, or other indoor facilities. The installation process involves the following steps:

- Planning and Design: The installation begins with planning and designing the network layout. This includes determining the optimal routing paths, identifying entry points, and selecting appropriate fiber optic cables for the application.

- Cable Routing: Fiber optic cables are routed through conduits, cable trays, or plenum spaces within the building. The cables are safely secured to ensure they are protected from damage and do not interfere with other building systems.

- Termination and Splicing: Once the cables are routed to their intended locations, they are terminated and spliced to connectors or patch panels. This process involves carefully stripping the cable, aligning and joining the fiber cores, and securing the connection with appropriate connectors or splices.

- Testing and Verification: After termination and splicing, the installed fiber optic cables undergo testing to ensure proper signal transmission and minimal loss. Various tests, such as optical power measurements and OTDR (Optical Time Domain Reflectometer) testing, are conducted to verify the integrity of the installed cables.

Outdoor Installations:

Outdoor installations involve routing fiber optic cables outside of buildings and across open areas. The installation process for outdoor applications may vary depending on the specific requirements and environmental factors. Here is a general outline of the steps involved:

- Path Planning and Survey: Before installation, a path survey is conducted to determine the best route for the fiber optic cables. This involves identifying potential obstacles, assessing the terrain, and ensuring the chosen path minimizes the risk of damage.

- Trenching or Duct Installation: In many cases, outdoor fiber optic cables are installed underground using trenching or duct installation methods. Trenching involves digging a narrow trench where the cables are buried at a certain depth. Duct installation involves placing the fiber optic cables inside protective conduits or ducts.

- Aerial Installation: In some cases, fiber optic cables are installed overhead using aerial installation methods. This involves attaching the cables to poles, utility lines, or dedicated aerial supports. Aerial installations are commonly used for long-distance telecommunication networks.

- Splicing and Termination: Once the cables are installed, splicing and termination procedures are carried out similar to indoor installations. The fiber optic cables are terminated with connectors or splices, allowing them to be connected to network equipment or other cables.

- Protection and Sealing: Outdoor fiber optic cables require proper protection against environmental factors such as moisture, water, and UV radiation. This may involve using protective enclosures, weatherproof seals, or burying the cables deeper in the ground.

- Testing and Commissioning: Similar to indoor installations, outdoor fiber optic cables undergo testing and commissioning to ensure proper signal transmission and minimal loss. Testing involves checking the optical characteristics of the installed cables and verifying their performance using appropriate testing equipment.

It's important to note that some specialized installations may involve deploying fiber optic cables underwater, such as for submarine communication cables or offshore applications. These installations typically require specialized equipment and expertise, and the cables are protected to withstand the underwater environment.

In summary, fiber optic cables can be installed both indoors and outdoors. Indoor installations involve routing cables within buildings, while outdoor installations utilize methods such as trenching, duct installation, or aerial placement. The specific installation method is determined by factors such as the environment, distance, and requirements of the network.

-

Difference between single-mode and multi-mode fiber optic cables?

-

Single-mode fiber (SMF) and multimode fiber (MMF) are two types of fiber optic cables used for different applications. The main difference between SMF and MMF lies in their core size and the way they transmit light signals. Here's a detailed explanation of SMF and MMF:

Single-Mode Fiber (SMF):

Single-mode fiber (SMF) is designed to propagate a single mode of light, allowing for long-distance transmission with minimal signal degradation. The core size of SMF is typically smaller, around 9 to 10 microns (μm) in diameter.

In SMF, the smaller core size enables the light to propagate in a straight line, eliminating the dispersion commonly found in multimode fibers. This minimizes signal loss and allows for higher bandwidth capacity and longer transmission distances.

Key features of SMF:

- Long Transmission Distances: SMF can transmit data over long distances without significant signal degradation. With advanced amplification techniques, SMF can achieve transmission distances of tens or even hundreds of kilometers without requiring signal regeneration or amplification.

- Higher Bandwidth: SMF provides a higher bandwidth capacity compared to MMF. It allows for higher data rates and can support applications with higher bandwidth requirements.

- Narrower Spectral Width: SMF has a narrower spectral width, which means it can transmit light at a specific wavelength with minimal dispersion. This allows for better signal integrity and less signal loss.

- Single Mode of Light Propagation: SMF allows only one mode of light to propagate, reducing the dispersion effects and maintaining signal quality over longer distances.

SMF is commonly used in applications where long-distance communication is required, such as telecommunication networks, long-haul transmission, and undersea communication cables.

Multimode Fiber (MMF):

Multimode fiber (MMF) is designed to propagate multiple modes of light simultaneously, allowing for shorter-distance transmission. The core size of MMF is larger than SMF, typically ranging from 50 to 62.5 microns (μm) in diameter.

In MMF, the larger core size accommodates multiple light paths or modes, which can lead to dispersion and signal loss over long distances. However, MMF is suitable for shorter-distance applications within buildings, campuses, or local networks.

Key features of MMF:

- Shorter Transmission Distances: MMF is typically used for shorter transmission distances, ranging from a few hundred meters to a few kilometers, depending on the type of MMF and the data rate being used.

- Lower Cost: MMF is generally more cost-effective compared to SMF. The larger core size makes it easier to manufacture, resulting in lower production costs.

- Higher Modal Dispersion: MMF experiences more modal dispersion compared to SMF due to the larger core size. This dispersion can limit the maximum distance of transmission and affect signal quality.

- Multiple Modes of Light Propagation: MMF allows multiple modes of light to propagate within the larger core, enabling greater tolerance to alignment and light source variations.

MMF is commonly used in applications such as local area networks (LANs), data centers, and short-distance communication within buildings.

In summary, the main difference between SMF and MMF lies in their core size and transmission characteristics. SMF has a smaller core size, supports a single mode of light propagation, and enables long-distance transmission with higher bandwidth. MMF has a larger core size, supports multiple modes of light propagation, and is suitable for shorter transmission distances within local networks or buildings.

-

How to terminate/connect fiber optic cables?

-

Terminating or connecting fiber optic cables involves the process of joining the fiber ends to connectors or splices, allowing them to be connected to devices or other cables. Here's a detailed explanation of how fiber optic cables are terminated or connected:

1. Connector Termination:

Connector termination involves attaching connectors to the ends of the fiber optic cables. This process enables easy, quick, and repeatable connections. The most common connector types used for termination are SC (Subscriber Connector), LC (Lucent Connector), ST (Straight Tip), and MPO (Multi-fiber Push-On).

The termination process generally follows these steps:

- Preparation: Start by stripping the protective layers of the fiber cable using precision stripping tools. This exposes the bare fiber.

- Cleaving: Use a fiber cleaver to create a clean, flat, and perpendicular end face on the fiber. The cleaver ensures a precise and smooth cut without inducing excessive loss or reflection.

- Cleaning: Clean the cleaved fiber end face using lint-free wipes and specialized fiber optic cleaning solutions. This step removes any debris, oils, or contaminants that could affect the connection.

- Connector Installation: Place the connector housing over the prepared fiber end and carefully secure it using epoxy or a mechanical mechanism, depending on the connector type.

- Curing: If epoxy is used, it needs to be cured according to the manufacturer's instructions. Ultraviolet (UV) light can be used to cure the epoxy, ensuring a strong and secure bond between the fiber and connector.

- Polishing: Once the connector is cured, the ferrule (the part of the connector that holds the fiber) is polished to achieve a smooth, flat, and low-reflection end face. This polishing step ensures optimum light transmission and reduces signal loss.

2. Splice Termination:

Splice termination involves permanently joining two fiber optic cables together using fusion splicing or mechanical splicing:

- Fusion Splicing: Fusion splicing involves aligning the fiber ends precisely and then fusing them together using an electric arc or laser. This creates a continuous connection with low loss and high strength. Fusion splicing is typically performed using specialized fusion splicing machines or equipment.

- Mechanical Splicing: Mechanical splicing involves aligning and mechanically securing the fiber ends using a precision alignment fixture and epoxy or a mechanical clamping mechanism. Mechanical splicing is less common than fusion splicing but can be used for temporary connections or in situations where fusion splicing is not feasible.

Both fusion splicing and mechanical splicing follow similar preparation steps before joining the fibers, such as stripping, cleaving, and cleaning.

3. Testing and Verification:

After termination or splicing, it is essential to perform testing and verification to ensure proper signal transmission and minimal loss. This typically involves using specialized testing equipment such as an optical power meter, optical time-domain reflectometer (OTDR), or optical loss test set (OLTS). These tests measure optical power levels, detect any loss or reflection points, and confirm the integrity of the terminated or spliced fiber connections.

It's important to note that terminating or connecting fiber optic cables requires precision and expertise to achieve optimal results. It is often recommended to have trained professionals or experienced technicians perform the termination process to ensure reliable and high-quality connections.

In summary, terminating or connecting fiber optic cables involves preparing the fiber ends, attaching connectors or splices, curing or fusing the connections, polishing (in the case of connectors), and performing testing and verification to ensure proper signal transmission.

-

Considerations for installing and handling fiber optic cables?

-

Yes, there are several special considerations to keep in mind when installing and handling fiber optic cables. These considerations are important to ensure the proper functioning and longevity of the cables. Here are the key points to consider:

- Bending Radius: Fiber optic cables have a specified minimum bending radius that should be adhered to during installation. Exceeding the bending radius can cause signal loss or even damage the cable. Avoid sharp bends and ensure that the cables are not kinked or tightly bent beyond the recommended radius.

- Pulling Tension: When pulling fiber optic cables during installation, it's crucial to avoid excessive tension. Excessive pulling force can stretch or damage the cables, causing signal loss or breakage. Use proper pulling techniques and equipment specifically designed for fiber optic cables to prevent over-tensioning.

- Protection from Mechanical Damage: Fiber optic cables are more delicate than traditional copper cables and require protection from mechanical damage. Ensure that the cables are properly protected from crushing, pinching, or sharp edges during installation. Use suitable conduits, cable trays, or protective tubing to prevent accidental damage.

- Avoiding Excessive Stress: Fiber optic cables are sensitive to excessive stress, such as tension or pressure, which can lead to signal loss or cable failure. Take care to avoid placing heavy objects on the cables or subjecting them to excessive pressure during installation or maintenance.

- Handling with Clean Hands: Fiber optic cables are highly sensitive to contaminants. When handling the cables, ensure that your hands are clean and free from dirt, grease, or oils. Contaminants on the fiber can cause signal loss or interfere with the connection quality.

- Avoiding Exposure to Chemicals: Fiber optic cables can be damaged by exposure to chemicals or solvents. Take precautions to prevent contact with chemicals such as cleaning agents, solvents, or corrosive substances during installation or when working in the vicinity of fiber optic cables.

- Protection from Environmental Factors: Fiber optic cables should be protected from environmental factors such as moisture, extreme temperatures, and UV radiation. Ensure that suitable weatherproofing measures are taken for outdoor installations, and consider using appropriate indoor cable management systems to protect against environmental factors within buildings.

- Labeling and Documentation: Proper labeling and documentation of fiber optic cables during installation are essential for future maintenance and troubleshooting. Clearly label the cables, connectors, and termination points to facilitate identification and minimize errors during maintenance or upgrades.

- Proper Testing and Verification: After installation, it is crucial to perform testing and verification to ensure the integrity and performance of the installed fiber optic cables. Use appropriate testing equipment to measure optical power levels, detect any losses or reflections, and verify the quality of the installation.

- Professional Installation and Maintenance: Fiber optic cables require specialized knowledge and tools for installation and maintenance. It is recommended to have trained professionals or experienced technicians handle the installation, termination, and maintenance of fiber optic cables to ensure reliable and high-quality connections.

By following these considerations, you can help ensure the successful installation, longevity, and optimal performance of fiber optic cables in your network or application.

-

Usability of fiber optic cables for video, audio, and data transmission?

-

Yes, fiber optic cables can be used for video, audio and data transmission. Fiber optic technology is versatile and capable of carrying a wide range of signals, including HD video, audio signals and digital data signals. Here's a detailed explanation:

Video and Voice Transmission:

Fiber optic cables are well-suited for high-definition (HD) video and audio transmission. Fiber optic technology provides several advantages that make it an excellent choice for delivering high-quality video and audio signals. Here's a detailed explanation:

- Bandwidth Capacity: Fiber optic cables have a much higher bandwidth capacity compared to traditional copper cables. This high bandwidth capacity allows for the transmission of large amounts of data, which is essential for delivering high-definition video and audio signals. Fiber optic cables can handle the high data rates required for HD video and audio, ensuring smooth and uninterrupted transmission.

- High-Speed Data Transfer: Fiber optic cables can transmit data at significantly faster speeds compared to copper cables. This is particularly essential for HD video and audio transmission, as these signals require a high data transfer rate to deliver a seamless viewing or listening experience. The faster data transfer speeds of fiber optic cables enable the transmission of high-definition content without latency or buffering issues.

- Low Signal Loss: Fiber optic cables experience minimal signal loss during transmission. This is particularly crucial for high-definition video and audio signals, as any loss in signal quality can result in a degradation of the viewing or listening experience. The low signal loss of fiber optic cables ensures that HD video and audio signals are delivered with high clarity and fidelity.

- Immunity to Electromagnetic Interference: Fiber optic cables are immune to electromagnetic interference (EMI) that can degrade signal quality. Copper cables are susceptible to EMI from nearby electrical equipment or power lines, which can introduce noise and distort the video or audio signals. Fiber optic cables, being made of glass or plastic, do not suffer from EMI, ensuring a clean and interference-free transmission of high-definition signals.

- Long Transmission Distances: Fiber optic cables can transmit high-definition video and audio signals over long distances without significant signal degradation. Copper cables, on the other hand, experience signal loss and attenuation over longer distances. This makes fiber optic cables ideal for applications that require long-distance transmission, such as distributing HD video and audio signals across large venues or campuses.

- Secure Transmission: Fiber optic cables provide a higher level of security for HD video and audio transmission. The data transmitted through fiber optic cables is more difficult to intercept compared to traditional copper cables. Additionally, fiber optic cables can be used with encryption protocols to ensure the secure transmission of sensitive HD content.

Data Transmission:

Fiber optic cables are particularly well-suited for high-speed data transmission. They can carry various types of digital data signals, including internet data, video data, and other forms of digital communication.

Fiber optic technology provides high bandwidth capacity and low transmission loss, enabling fast and reliable data transmission over long distances. This is especially important for data-intensive applications such as internet browsing, file transfers, video streaming, cloud computing, and other data-driven processes.

The high bandwidth capabilities of fiber optic cables allow for the simultaneous transmission of large volumes of data, making them ideal for networks with heavy data traffic. The lower latency and minimal signal degradation of fiber optic cables also contribute to improved data transmission performance.

Fiber optic cables can support various data transmission protocols, including Ethernet, SONET/SDH, Fibre Channel, and others, making them compatible with a wide range of network systems and data communication technologies.

In summary, fiber optic cables can effectively handle both voice and data transmission. They can transmit analog voice signals as well as digital voice signals in the form of VoIP. Additionally, fiber optic cables can efficiently carry data signals, providing high-speed, reliable, and secure data transmission for various applications.

-

Testing performance and quality of fiber optic cables in a network?

-

Testing the performance and quality of fiber optic cables in a network is crucial to ensure optimal signal transmission and identify any issues or faults. Here's a detailed explanation of how you can test the performance and quality of fiber optic cables:

1. Optical Power Measurement:

Optical power measurement is a fundamental test to determine the strength of the optical signal in the fiber optic cable. This test verifies that the power level falls within the acceptable range for proper operation. It involves using an optical power meter to measure the received power at various points in the network. Comparing the measured power levels with the expected values helps identify any power losses or irregularities.

2. Optical Loss Testing:

Optical loss testing, also known as insertion loss testing, measures the overall signal loss in a fiber optic cable or a link. This test verifies the performance of connectors, splices, and the overall fiber optic link. It involves connecting an optical source and a power meter at each end of the cable or link and measuring the power loss. Optical loss testing helps identify high-loss points, faulty connectors, or improperly spliced sections.

3. Optical Time-Domain Reflectometry (OTDR):

Optical Time-Domain Reflectometry (OTDR) is a powerful testing technique that provides detailed information about the fiber optic cable, including its length, the locations of splices, connectors, and any faults or breaks. An OTDR sends a pulse of light into the fiber and measures the reflected light as it bounces back. This allows it to detect and locate issues such as breaks, bends, excessive losses, or mismatches. OTDR testing is particularly useful for long-haul or outdoor fiber optic links.

4. Chromatic Dispersion and Polarization Mode Dispersion (PMD) Testing:

Chromatic dispersion and polarization mode dispersion (PMD) are two phenomena that can affect the quality of transmitted signals in fiber optic cables. Chromatic dispersion occurs when different wavelengths of light travel at different speeds, leading to signal distortion. PMD is caused by variations in the propagation speed of light in different polarization states. Both chromatic dispersion and PMD can limit the transmission distance and data rates. Specialized testing equipment is used to measure and assess these parameters, ensuring the fiber optic cable meets the required performance specifications.

5. Bit Error Rate Testing (BERT):

Bit Error Rate Testing (BERT) measures the quality of the transmitted signal by assessing the number of bit errors occurring during transmission. BERT testing involves transmitting a known pattern of bits through the fiber optic cable and comparing the received pattern with the transmitted one. This test helps identify issues such as excessive noise, signal degradation, or other impairments that can affect the data integrity and performance of the fiber optic link.

6. Connector End Face Inspection:

Inspecting the connector end faces is a visual examination that ensures the cleanliness and quality of the connectors. Dust, dirt, or contamination on the connector end faces can cause signal loss or degrade the connection quality. The inspection is done using a fiberscope or microscope to examine the connector surface and identify any defects, scratches, or contaminants. Regular cleaning and inspection of connector end faces help maintain the performance of fiber optic cables.

7. Fiber Link Certification:

Certification tests involve a comprehensive evaluation of the entire fiber optic link, including inspection, optical loss testing, and verification of other parameters. Certification testing ensures that the fiber optic link meets the required industry standards and specifications. Certification testing is typically performed using specialized fiber certification equipment and software.

It is important to note that testing procedures and equipment may vary based on the specific requirements and standards of the fiber optic network. Trained technicians or professionals with expertise in fiber optic testing should perform these tests to ensure accuracy and reliability.

By conducting these tests, you can assess the performance and quality of fiber optic cables in your network, detect any issues or faults, and take appropriate measures to rectify them, ensuring reliable and efficient communication.

-

Security of fiber optic cables against eavesdropping and interception?

-

Fiber optic cables provide a higher level of security compared to other types of cables, making them more secure from eavesdropping and data interception. Here's a detailed explanation:

- Physical Security: Fiber optic cables are more difficult to tap into compared to copper cables. Copper cables emit electromagnetic signals that can be intercepted and monitored. In contrast, fiber optic cables transmit data using pulses of light, which do not emit electromagnetic signals that can be easily intercepted. This physical security feature makes fiber optic cables less susceptible to external eavesdropping.

- Signal Loss: Fiber optic cables experience minimal signal loss during transmission. Any attempt to tap into the fiber optic cable and extract data will cause a significant loss in signal strength, making it difficult to intercept and decipher the information being transmitted. This loss of signal is noticeable and can alert network administrators to potential eavesdropping attempts.

- Light-Based Transmission: Fiber optic cables use light-based transmission, which presents another level of security. Since the data is transmitted as pulses of light, it is difficult to intercept the signal without disrupting the transmission itself. When an unauthorized attempt is made to tap into the fiber optic cable, it causes a break or interruption in the light signal, alerting network administrators to the tampering attempt.

- Encrypted Data: While fiber optic cables themselves do not provide encryption, the data transmitted through these cables can be encrypted. Encryption involves encoding the data in a way that can only be decoded by authorized parties with the appropriate encryption keys. By encrypting the data, even if an unauthorized individual manages to intercept the transmitted data, they would not be able to decipher the encrypted information.

- Secure Network Infrastructure: Fiber optic cables are often used within a secure network infrastructure. This includes implementing other security measures such as firewalls, intrusion detection systems, and data encryption protocols. These additional security measures strengthen the overall security of the network and enhance protection against eavesdropping and data interception.

- Difficulty in Tapping: The physical characteristics of fiber optic cables make it challenging to tap into the cable without detection. Compared to copper cables, which can be easily tapped into by simply making a physical connection, tapping into fiber optic cables requires more sophisticated and specialized equipment. This adds an extra layer of security and makes it more difficult for unauthorized individuals to intercept data.

While fiber optic cables provide a higher level of security compared to other types of cables, it's important to note that no system is completely immune to all types of attacks. It is still advisable to implement additional security measures and follow best practices to protect sensitive data and maintain network security.

-

Typical lifespan of fiber optic cables?

-

Fiber optic cables have a long lifespan that can extend for several decades. The typical lifespan of fiber optic cables depends on various factors, including the quality of the cables, the installation environment, and the maintenance practices. Here's a detailed explanation:

Quality of Fiber Optic Cables:

The quality of fiber optic cables plays a significant role in determining their lifespan. High-quality cables manufactured by reputable manufacturers tend to have a longer lifespan compared to lower-quality or counterfeit cables. High-quality cables are designed to withstand environmental factors and maintain signal integrity over extended periods.

Installation Environment:

The installation environment of fiber optic cables can impact their lifespan. Cables installed in controlled environments, such as indoor settings or underground conduits, are typically exposed to fewer external stresses and have a longer lifespan. On the other hand, cables installed in harsher environments, such as aerial installations, underwater deployments, or outdoor installations with extreme temperatures or humidity, may have a slightly shorter lifespan due to increased exposure to environmental factors.

Maintenance Practices:

Regular maintenance and proper handling can significantly extend the lifespan of fiber optic cables. Periodic inspections, cleaning, and preventive maintenance activities can help identify and address issues that may impact the cables' performance and longevity. Additionally, following best practices for installation, such as maintaining proper bend radii and protecting cables from physical damage, can also contribute to the longer lifespan of the cables.

Industry Standards and Warranties:

Fiber optic cables are typically designed and manufactured according to industry standards and specifications. These standards often define the expected lifespan of the cables under normal operating conditions. Additionally, reputable manufacturers often provide warranties for their cables, which can give customers assurance of the expected lifespan.

Lifespan Expectations:

While there is no fixed number for the lifespan of fiber optic cables, it is not uncommon for well-installed and well-maintained fiber optic cables to last for 20 to 30 years or more. In fact, there have been instances where fiber optic cables installed several decades ago are still functioning reliably today. As long as the cables are not subjected to excessive stress, physical damage, or environmental factors that degrade their integrity, they can provide reliable performance over an extended period.

It's important to note that technological advancements and evolving industry standards may lead to the deployment of newer fiber optic technologies in the future. Upgrading to newer technologies may offer improved performance and capabilities, even if the existing cables are still functioning within their expected lifespan.

In summary, the typical lifespan of fiber optic cables can extend for several decades if they are high-quality, installed thoughtfully, maintained properly, and operated in suitable environments. Following industry standards, manufacturer recommendations, and regular maintenance practices can help ensure the longevity and reliable performance of fiber optic cables in a network.

-

Suitability of fiber optic cables in extreme conditions?

-

Fiber optic cables can be used in harsh environmental conditions, including extreme temperatures and high humidity. However, it's important to consider certain factors and select the appropriate types of fiber optic cables that are specifically designed for such conditions. Here's a detailed explanation:

Extreme Temperatures:

- High Temperatures: Fiber optic cables can be designed to withstand high temperatures, allowing them to be used in environments where temperatures reach or exceed normal operating ranges. Specialized cables with high-temperature resistant materials, such as high-temperature acrylate or polyimide coatings, are available for applications such as industrial processes, aerospace, or high-temperature manufacturing.

- Low Temperatures: Fiber optic cables can also be designed to withstand low temperatures, enabling their use in extremely cold environments. Cables with low-temperature-rated materials, such as low-smoke zero-halogen (LSZH) or low-temperature acrylate coatings, are suitable for applications in cold storage facilities, arctic regions, or outer space.

It's important to choose fiber optic cables with appropriate temperature ratings to ensure their reliable operation in extreme temperature conditions. Higher quality cables typically offer wider temperature ranges for deployment.

High Humidity and Moisture:

- Outdoor and Indoor Humidity: Fiber optic cables used in outdoor or indoor environments with high humidity levels should be designed with water-resistant or water-blocking properties. These cables often have gel-filled or tight-buffered constructions that prevent moisture from penetrating the cable and causing signal degradation.

- Underwater or Submerged Applications: Fiber optic cables designed for underwater or submerged applications, such as underwater communication links or marine environments, are specially engineered to be water-resistant and corrosion-resistant. These cables have additional protective layers, such as water-blocking materials and robust outer jackets, to withstand prolonged exposure to water and moisture.

Cables designed for harsh environmental conditions often comply with specific industry standards or certifications, such as the International Electrotechnical Commission (IEC) or National Electrical Manufacturers Association (NEMA) standards. These standards define the environmental conditions under which the cables can operate reliably.

It's worth mentioning that extreme environmental conditions can still impact the performance of fiber optic cables. Therefore, it is important to consider additional protective measures, such as proper cable management, sealing entry points, or using protective enclosures, to safeguard the cables from external factors that could compromise their performance.

In summary, fiber optic cables can be used in harsh environmental conditions, including extreme temperatures and high humidity, provided that they are specifically designed and rated for those conditions. By selecting cables with appropriate temperature and moisture resistance ratings, and implementing proper protective measures, fiber optic cables can reliably function in a wide range of demanding environmental scenarios.

-

Handling bends and turns with fiber optic cables?

-

Fiber optic cables can handle bends and turns to a certain extent, but there are limitations that need to be considered to ensure optimal performance and avoid signal loss. Here's a detailed explanation:

Bending Radius:

Fiber optic cables have minimum bending radius specifications that define the smallest radius at which they can be bent without causing signal degradation. The bending radius is typically specified by the cable manufacturer and depends on the cable type and design. It is important to adhere to these specifications to prevent excessive loss or damage to the fiber.

Single-Mode Fiber (SMF):

Single-mode fiber (SMF) has a smaller core size and is more sensitive to bending compared to multimode fiber. SMF generally has a stricter bending radius requirement to maintain optimal signal quality. Bending SMF beyond the recommended radius may result in increased attenuation, loss of signal power, or even breakage of the fiber.

Multimode Fiber (MMF):

Multimode fiber (MMF) typically has a larger core size, which allows for greater tolerance to bending compared to SMF. MMF generally has a more relaxed bending radius requirement. However, it is still important to adhere to the manufacturer's specifications to avoid any potential signal loss or impairment.

Limitations and Considerations:

Despite the bending flexibility of fiber optic cables, there are some limitations and considerations to keep in mind:

- Minimum Bending Radius: Exceeding the minimum bending radius specified by the cable manufacturer can lead to increased signal loss, attenuation, and potential damage to the fiber. It is important to follow the manufacturer's recommendations for the specific cable type.

- Bend-Insensitive Fiber: Some fiber optic cables are designed with bend-insensitive fibers. These fibers have improved performance in tight bend scenarios, allowing for greater flexibility in cable routing. Bend-insensitive fibers can handle tighter bends without significant signal loss.

- Installation Techniques: Proper cable installation techniques, such as using gradual bends and avoiding sharp kinks, are crucial to maintaining signal integrity. Installing cables with excessive force or bending them at sharp angles can cause fiber misalignment, increased attenuation, or even fracture the fiber.

- Bend-Optimized Cables: Bend-optimized fiber optic cables are available in the market specifically designed to withstand tighter bends without sacrificing performance. These cables employ specialized fiber designs or coatings that reduce signal loss in bending scenarios.

- Long-Term Effects: While fiber optic cables can tolerate temporary bends during installation or maintenance, long-term or permanent bends can have cumulative effects that degrade the cable's performance over time. Prolonged bending can result in increased signal degradation or failure of the fiber.

- Fiber Types and Cable Construction: Different fiber types and cable constructions have varying bending characteristics. It is essential to select the appropriate fiber type and cable construction based on the specific application requirements and the expected level of bending flexibility needed.

In summary, fiber optic cables can handle bends and turns to a certain extent, but there are limitations and considerations to ensure optimal performance. It is important to adhere to the manufacturer's specifications for minimum bending radius and use proper installation techniques to avoid excessive signal loss, attenuation, or damage to the fiber. By following these guidelines, fiber optic cables can maintain reliable signal transmission even when subjected to bends and turns within their specified limits.

-

Connector types used with fiber optic cables?

-

There are several different connector types used with fiber optic cables, each with its own characteristics, advantages, and applications. Here's a detailed explanation of some commonly used connector types:

1. SC (Subscriber Connector):

SC connectors are one of the most popular connector types. They feature a square-shaped, push-pull coupling mechanism that ensures secure connections. SC connectors are easy to install and remove, making them widely used in data communication networks, telecommunication systems, and cable television (CATV) applications.

2. LC (Lucent Connector):

LC connectors are smaller in size compared to SC connectors. They use a push-pull coupling mechanism similar to SC connectors, making them easy to install and remove in high-density environments. LC connectors are commonly used in data center applications, fiber-to-the-home (FTTH) installations, and high-speed networking applications.

3. ST (Straight Tip):

ST connectors have a round, bayonet-style coupling mechanism. They are relatively easy to install and provide secure connections. ST connectors are commonly used in local area networks (LANs), premises cabling, and fiber optic networks that require reliable and robust connections.

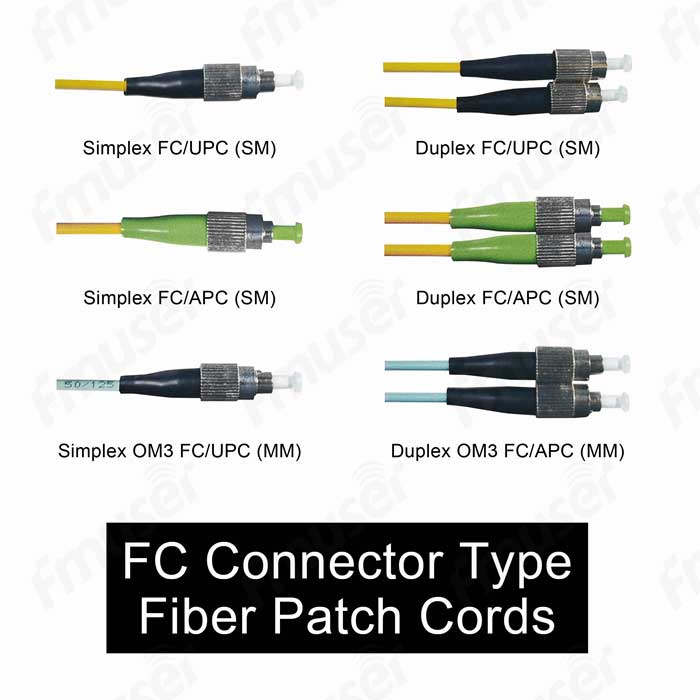

4. FC (Ferrule Connector):

FC connectors use a threaded coupling mechanism that provides a more secure and stable connection. They are commonly used in telecommunication networks, test equipment, and high-precision applications that require highly accurate alignment.

5. MTRJ (Mechanical Transfer Registered Jack):

MTRJ connectors are duplex connectors, meaning they have two fibers in a single connector. They use a push-pull latching mechanism similar to that of an RJ45 connector used in Ethernet connections. MTRJ connectors are widely used in premises cabling, data transmission, and multimedia applications.

6. MT-RJ (Mechanical Transfer - Registered Jack):

MT-RJ connectors are also duplex connectors that combine two fibers in a single connector. They feature a push-pull latching mechanism and are smaller in size compared to MTRJ connectors. MT-RJ connectors are commonly used in high-density applications, such as data centers and telecommunication networks.

7. MPO/MTP (Multi-fiber Push-On/Multi-fiber Termination Push-on):

MPO/MTP connectors are multi-fiber connectors that can accommodate multiple fibers in a single connector. They are widely used in high-density applications such as data centers and backbone networks. MPO/MTP connectors enable quick and efficient connections for high-bandwidth applications, including high-speed data transmission and parallel optics.

These connector types mentioned above represent some of the most commonly utilized ones. There are other connector types available as well, each designed for specific applications or industry requirements. It's important to consider factors such as ease of installation, density requirements, and compatibility with the equipment when selecting the appropriate connector type for a specific fiber optic installation.

-

Feasibility of upgrading or expanding fiber optic cables?

-

Fiber optic cables provide flexibility for future upgrades and expansions in a network. Here's a detailed explanation of how fiber optic cables can be easily upgraded or expanded:

1. Scalability:

Fiber optic cables offer scalability, allowing for future upgrades and expansions without the need for significant infrastructure changes. The high bandwidth capacity of fiber optic cables enables the transmission of large amounts of data, accommodating future growth and increasing bandwidth requirements.

2. Upgrading Network Equipment:

Upgrading or expanding a fiber optic network can often be achieved by upgrading the network equipment connected to the existing fiber optic cables. As technology evolves and higher data rates become available, network equipment such as switches, routers, and transceivers can be upgraded to support the new standards. The existing fiber optic cables can remain in place, as they are capable of handling the increased data rates.

3. Compatibility with New Technologies:

Fiber optic cables are compatible with various transmission technologies, protocols, and data rates. This compatibility allows for seamless integration of new technologies and equipment in the future. As long as the new equipment and technologies are compatible with the fiber optic cables' specifications, upgrading or expanding the network becomes relatively straightforward.

4. Passive Optical Network (PON) Architecture:

Fiber optic networks that use Passive Optical Network (PON) architecture are particularly suitable for future upgrades and expansions. PONs allow for shared fiber infrastructure, enabling multiple users to share the same fiber optic cables. Upgrades within a PON can often be achieved by adding or upgrading optical line terminals (OLTs) and optical network units (ONUs) without the need to change the fiber optic cables.

5. Fiber Splicing and Connectors:

Fiber optic cables can be expanded or extended by splicing additional fiber optic cables to the existing ones. Fiber splicing involves permanently joining fiber optic cables using fusion splicing or mechanical splicing techniques. This allows for extending the network or connecting new network segments without the need for major cable replacements.

Moreover, connectors can be used to connect additional fiber optic cables or equipment to the network. The connectors provide a removable and reconfigurable means of adding or removing fibers or connections as needed.

6. Future-Proofing:

Fiber optic technology is considered future-proof, meaning it can accommodate future advancements and higher speeds. As the demand for faster data transmission increases, fiber optic cables provide the necessary infrastructure to support these advancements without requiring significant changes to the physical cabling.

In summary, fiber optic cables provide the flexibility and scalability required for future upgrades and expansions in a network. They can be easily upgraded by replacing or upgrading network equipment, utilizing compatible technologies, splicing additional cables, or using connectors to connect new equipment or segments. Fiber optic cables are designed to accommodate future advancements, making them an excellent choice for long-term network planning and growth.

-

Health concerns associated with fiber optic cables?

-

Fiber optic cables do not pose significant health concerns related to radiation or electromagnetic fields. Here's a detailed explanation:

1. No Radiation Emissions:

Fiber optic cables use light-based transmission to transmit data, which means they do not emit any form of radiation. Unlike wireless communication technologies or certain electrical cables, fiber optic cables do not generate electromagnetic radiation such as radio waves, microwaves, or X-rays. Therefore, there is no risk of exposure to harmful radiation from fiber optic cables.

2. Immunity to Electromagnetic Interference (EMI):

One of the advantages of fiber optic cables is their immunity to electromagnetic interference (EMI). Unlike copper cables, fiber optic cables do not conduct electricity, making them highly resistant to EMI. This immunity to EMI ensures that fiber optic cables do not generate or amplify electromagnetic fields that can potentially interfere with sensitive electronic equipment or cause health concerns.

3. Safety in Electrical Environments:

Fiber optic cables are often chosen for their safety in potentially hazardous environments. They are non-conductive and do not carry electrical current, eliminating risks associated with electrical shock or fire hazards. This characteristic makes fiber optic cables particularly suitable for use in industrial settings, power plants, or areas with high-voltage equipment.

4. No Electromagnetic Sensitivity:

Fiber optic cables are not affected by external electromagnetic fields or electrical noise. Unlike copper cables, which can be susceptible to interference from nearby power lines or electrical equipment, fiber optic cables are immune to electromagnetic disturbances. This immunity ensures that the transmitted data remains unaffected and maintains its integrity.

5. No Health Risks from Fiber Optic Signals:

The light signals used in fiber optic cables are harmless to human health. Fiber optic signals are typically low-power and travel within the fiber without spreading into the surrounding environment. This eliminates any potential health risks associated with exposure to the transmitted light signals.

In summary, fiber optic cables do not pose significant health concerns related to radiation or electromagnetic fields. They do not emit any radiation, are immune to electromagnetic interference, and are considered safe in electrical environments. Fiber optic cables provide a secure and reliable means of data transmission without any associated health risks.

-

Comparison of cost and maintenance with other cable types?

-

When it comes to cost and maintenance, fiber optic cables have certain advantages and considerations compared to other types of cables like copper or coaxial cables. Here's a detailed explanation:

Cost:

- Installation Cost: The initial installation cost of fiber optic cables is typically higher than that of copper or coaxial cables. Fiber optic cables require specialized tools and expertise for installation. Additionally, the cost of fiber optic connectors, termination equipment, and fusion splicers can contribute to higher upfront expenses.

- Long-Term Cost: Fiber optic cables have a significant advantage in terms of long-term cost. They generally require less maintenance and have higher reliability, resulting in lower maintenance and repair expenses over time. Fiber optic cables are less susceptible to electromagnetic interference, corrosion, and signal loss, reducing the need for frequent replacement or repairs.

- Bandwidth Capacity: Fiber optic cables offer a higher bandwidth capacity compared to copper or coaxial cables. This higher capacity allows for more data transmission and supports higher-speed networks. While fiber optic cables may have a higher upfront cost, the increased bandwidth can accommodate future data requirements, potentially reducing the need for costly upgrades in the future.

Maintenance:

- Durability and Reliability: Fiber optic cables are highly durable and reliable. They are less prone to damage from environmental factors such as temperature fluctuations, moisture, and electromagnetic interference. This reliability reduces the need for frequent maintenance or replacement.

- Signal Integrity: Fiber optic cables are less susceptible to signal loss and interference compared to copper or coaxial cables. This means that the quality of the transmitted signals remains high, resulting in better network performance and fewer maintenance issues.

- Lower Maintenance Requirements: Fiber optic cables have fewer maintenance requirements compared to copper or coaxial cables. They are not affected by corrosion, and their lightweight and flexible nature make installation and maintenance easier. Additionally, fiber optic cables do not require periodic re-termination like copper cables, which can reduce maintenance efforts and costs.

- Reduced Downtime: Due to their reliability and signal integrity, fiber optic cables often experience fewer outages or downtime compared to copper or coaxial cables. This translates to lower maintenance costs associated with diagnosing and resolving network issues.

- Faster Troubleshooting: In the event of network issues, troubleshooting fiber optic cables is generally faster and more efficient. Fiber optic cables can be tested using specialized equipment such as OTDR (Optical Time-Domain Reflectometer), which provides detailed information about the cable's performance and helps pinpoint the exact location of any faults or breaks.

In summary, while fiber optic cables may have higher upfront costs for installation, they offer long-term cost savings due to lower maintenance requirements and higher reliability. Fiber optic cables also provide advantages in terms of bandwidth capacity and signal integrity. These factors contribute to better network performance, reduced downtime, and more efficient troubleshooting. Considering the long-term benefits, fiber optic cables can be a cost-effective choice for reliable and high-performance network infrastructure.

- How are you?

- I am fine

CONTACT US

FMUSER INTERNATIONAL GROUP LIMITED.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us